Federal Republic of Germany (1977)

Federal Republic of Germany (1977)

Mine Clearing Vehicle – 24 Built

The most effective and safe way of clearing a path through mine-laden ground has long been debated. Do you remove it from the ground, as with a mine plow? Or do you detonate it where it sits, as with a line charge or other means of sympathetic detonation? Mine Flails – which were first deployed by the British in the Second World War aboard tanks such as the Sherman Crab – are one of the less extreme methods of the latter technique. These flails consist of a rotating drum suspended from the front of the vehicle, to which are connected a series of chains. The drum rotates at a high speed, causing the chains to pummel the ground, detonating any mines that may be buried.

The German Minenräumpanzer Keiler is one of these tanks. It is known as a Mine Detection and Clearing Vehicle or ‘MDCV’. The Keiler was the Kaelble Company’s answer to a 1971 request from the West German Federal Ministry of Defence for a mine-clearing vehicle. The MOD asked a number of German arms companies to design such a vehicle, but it was Kaelble’s flail vehicle that received military approval in 1983.

After a period of further development, Rheinmetall was contracted for the construction of the vehicle which would be based on the American M48 Patton. Rheinmetall completed and unveiled the first prototypes in 1985. A full-scale production contract was awarded in 1993, with the vehicles finally entering service with the Bundeswehr between 1997 and 1998.

The Minenräumpanzer Keiler. This vehicle belongs to the Gebirspionier 8 and was photographed in 2014. Photo: Ralph Zwilling, Tankograd Publishing

Development

The 1971 request from the West German Federal Ministry of Defence was, in fact, a trilateral endeavor between West Germany, France and Italy, based on a mutually agreed tactical needs and requirements. Numerous companies were lobbied and a design contest was held. The companies that submitted designs were Rheinstahl, Industriewerke Karlsruhe, Krupp MaK Maschinenbau (now Rheinmetall Landsysteme), AEG/Telefunken, Dynamit Nobel and Carl Kaelble. In 1972, Italy pulled out of the project, followed in 1976 by France, leaving the project to become a solely West German endeavor.

Trials with functional prototypes of the clearing equipment from each company followed. Mine flail systems appeared to be the most successful, at it was Kaelble’s design that grabbed the MOD’s attention. It consisted of a complex flail rig, mounted atop a tank chassis. When not in use, the rig could be stored atop the vehicle, and then pivoted around and down for clearing operations. Several further contracts were signed with Kaelble to develop and produce further operational flail system prototypes based on this design. In 1982, Krupp MaK Maschinenbau was chosen as the overall contractor and was subsequently contracted to build two trial vehicles that Kaelble’s flail could be mounted on. These vehicles would be known simply as ‘01’ and ‘02’. They were constructed in close cooperation with MTU, Renk and of course, Carl Kaelble. MTU would handle propulsion, Renk the transmission and Kaelble the mine-clearing equipment.

Prototype of what would become the Keiler undergoing field trials. Photo: Bundeswher/Tankograd Publishing

By 1985, both ‘01’ and ‘02’ were ready for field, troop and technical trials. They took part in numerous tests at Bundeswehr (German Army, also known as ‘Heer’) field ranges and test centers in the first quarter of 1985. ‘01’ was sent for tests in Arctic conditions in Norway. After passing the trials, ‘01’ was given to Rheinmetall as a reference subject for series production. In Germany, where ‘02’ was under trial, the vehicle cleared a total of 54 live mines without any damage to the vehicle or mine clearing apparatus. In total, 25 kilometers (15 miles) of safe lanes were cleared in the tests without issue.

Prototype vehicle ‘01’ in operation in Mostar, Bosnia, 1996. Photo: military-today.com

On October 1st, 1991, authorization was given for the vehicle, now designated the Minenräumpanzer Keiler’ (MiRPz, Eng: Flail Tank, Wild Boar), to enter full-scale production and enter service.

Production Confusion

The latter part of the Cold War was an economically unstable period, which lead to some confusion and a number of re-evaluations of just how many MiRPz. Keiler vehicles should be produced. In 1975, around the time of the vehicle’s initial conception, it was expected that the Bundeswehr would purchase 245 vehicles. By 1982, the figure had been reduced to 157, with it dropping again in 1985 to 50. With the vehicle’s acceptance into service in 1991, the Bundeswehr pushed the order back up to 72 units. However, with the Cold War now coming to an end, the German Army went through a period of budget cuts and restructuring. This resulted in a single production run of a 24-vehicle batch, running from 1996 to 1998. These vehicles were delivered straight to Pionierkompanies, the engineer units of the Bundeswehr.

Base Vehicle, the M48

Kaelble’s mine clearing device needed a suitable carriage. The developers, not wanting to sacrifice the Bundeswehr’s serving tanks, opted for a recently retired tank. The tank they chose was the American origin M48A2GA2. The M48 Patton, designated the Kampfpanzer (KPz) M48 in Germany, was one of many American tanks supplied to the fledgling West German Army in the 1950s The GA2 was an indigenous German upgrade to the tank which, among other smaller things, replaced the original 90mm gun with the infamous 105mm L7 gun.

Body of the Beast

The M48 hull went through a complete metamorphosis to turn it into the Keiler. The only recognizable feature left over from the M48 is the bulbous nose, driver’s hatch and running gear. The running gear and suspension did not escape modification though. Although the torsion bar suspension was retained, vibration dampeners were installed into the suspension components to make the vehicle a little more pleasant to operate for the crew when the mine flail is in operation. Also, in a recent upgrade program that took place in 2015, the original American made rubber chevron T97E2 tracks were replaced by German-made flat rubber tile 570 FT tracks, as found on the Leopard 2 tank. These tracks allow the Keiler to operate without restriction in Arctic conditions and necessitated the addition of new teeth to the sprocket wheel.

Profile photo of the Keiler showing the distinctive M48 Patton running gear. This is, perhaps, the only recognizable feature of the M48 within. Photo: Ralph Zwilling

The engine compartment remained at the rear of the vehicle, and for the majority of its service life retained the same powerpack as the M48, this being the 750hp Continental engine and General Motors transmission. This propelled the vehicle to a top speed of around 45 km/h (28mph). Unfortunately, performance data of this engine while the flail was in operation is unavailable at the time of writing. As part of the 2015 upgrades, the old powerpack made way for an engine made by MTU (Motoren- und Turbinen-Union meaning, Eng: Motor and Turbine Union), and a 6-speed (4 forward, 2 reverse) transmission by Renk. The engine is the MB 871 Ka-501. It is liquid cooled, 8-cylinder, turbocharged diesel engine producing around 960 hp when in travel mode. When in mine-clearing mode, the engine produces 1112hp. This engine propels the 56-tonne vehicle to a top forward speed of 48 km/h (30 mph), and it can also reverse at a respectable 25 km/h (15 mph). Due to the fact that the engine was used to propel both the vehicle and the flail, the Keiler had a high fuel consumption. So much so that it has developed a bad reputation for being a ‘gas guzzler’.

The upper hull of the M48 saw the heaviest modification. The turret was removed and a new, shallow superstructure built up atop the vehicle. This structure had a completely flat roof on top to accommodate the flail equipment in the travel position. This roof extends forward into a protective overhang above the driver’s position. The commander’s position is located roughly halfway down the length of the vehicle, slightly off center to the right of the hull. There is a vision cupola above his station.

The Keiler in operational mode. Note the flat roof with Commander’s cupola, the smoke grenade launchers on the engine deck and the various air intakes. The large box hanging off the rear of the vehicle is the ‘CLAMS’ Clear Lane Marker System. Photo: Wikimedia Commons

A number of different vents were added to the engine deck to provide air to the various pieces of equipment on board, including the new, more powerful engine. The most prominent of these are the large cooling-air intakes that hang over the fenders of the vehicle, just above the sprocket wheel. Further, smaller intakes can be found on the left and right of the vehicle, above the fifth and sixth road wheels. These provide air into the engine for combustion. An intake that brings air to the engine’s cooling fan can also be found on the left side of the vehicle. The large overhanging intakes can be folded to reduce the width of the vehicle when traveling under its own power or via transport.

The large cooling air intakes on the rear of the vehicle. Note also the smaller air intakes on the side of the vehicle. Photo: Ralph Zwilling

The Keiler is completely devoid of any offensive armament. The only defense the vehicle has is a rack of 76mm smoke grenade launchers mounted on the left of the engine deck, in front of the left overhanging air intake. It consists of a bank of 16 launchers, divided into two rows of 8 side-by-side barrels. The grenades are fired 1 side at a time, launching all 8 at once. The grenades fly around 50 meters and cover a 45 Degree arc on each side of the vehicle. For safety reasons, the launchers are electrically blocked from firing if the crew hatches are open.

The Boar’s Tusks

In the wild, the boar uses its specially adapted head to dig through the soil in search of food. Similarly, the mechanical beast that bears this swine’s name uses its specially adapted ‘head’ to detonate buried explosives, or throw them clear of the vehicle. Designed by Carl Kaelble, the flail installed on the Keiler remains one of the most sophisticated in existence.

The clearing apparatus of the MiRPz Keiler in travel mode, aligned horizontally atop the hull. The flail arms are lifted to a 90 Degree angle for storage so a travel lock (note the rod stretching from the hull to the central arm) can be attached. Spare flail elements are stored on the left sponson. This is an older photo, showing the Keiler with the original American tracks and sprocket wheel. Photo: Jürgen Plate

An innovative and rather unique feature of the Keiler is its fold-away flail that can be placed in a ‘travel mode’. The whole flail unit is attached to a single pivoting arm, rooted at the front left of the upper hull. For travel mode, the entire unit is stored horizontally along the length of the vehicle. For operation, the arm swings the equipment around 110 Degrees to the front end of the hull. The flail equipment is then lowered into place, locking into two horn-like supporting hydraulic rams. These control the up and down movements of the unit. A large shield underneath the bow of the vehicle protects these hydraulic ‘horns’ from exploding mines. In travel mode, this shield is stored up against the lower glacis and held in place by a chain. When clearing, the shield is hydraulically lowered into touching distance to the ground. Pitch of the flail is controlled by hydraulics connected to a crescent-shaped bar on top of the frame.

The bow of the Keiler. Note the tusk-like hydraulic rams on the left, and the lowered blast shield. Photo: Public Domain.

The flail assembly is supported by a carrier frame, consisting of three arms, all connected to one long cylinder which contains the axial-piston hydraulic engines which power the rotation of the clearing shaft. The shaft is in two parts, connected from the far right arm to the central arm, and the far left arm to the central arm. The shafts are staggered with the right shaft further forward than the left. Each shaft is equipped with 24 chains, at the end of each chain is a 25kg solid metal weight, or ‘element’, shaped like an elongated bell with notches cut into the end. Due to this shape, the metal weights have become known as ‘Elephant’s feet’. It is recommended that these elements are replaced after every 3,000 meters of clearance. Six spare elements are carried on board the vehicle during clearing operations. When in travel position the chains are wrapped around the rotating shafts and ratchet-strapped down.

The Keiler’s flail assembly. Note the 24 flail chains, each equipped with 25kg ‘Elephant’s foot. The rods at each end of the assembly are for measuring ground level. Photo: Ralph Zwilling

In the operational position, the flail is set at a permanent 20 degree oblique angle from the direction of travel (simply put, the left side of the carrier frame sits closest to the hull than the right side). The shafts rotate anti-clockwise at 400 revolutions per minute, meaning the ‘Elephants feet’ pummel the ground at a speed of around 200 km/h. Any mine encountered is either detonated, smashed beyond use, or kicked out of the path of the vehicle. It is estimated that between 98 and 100-percent of explosives are cleared during operation. Clearance depth is electro-mechanically governed by the ground level measuring rods found at the ends of the carrier frame. (These are stored on the rear of the vehicle in travel mode). They are in permanent contact with the ground, and the measurements they record are set via hydraulics, keeping a constant clearing depth. The flail clears a path 4.7 meters wide with a typical clearance depth that can be set between +50 and -250mm. When surface clearing at +50mm, the speed of the vehicle is 4 km/h, for deeper clearing this is reduced to 2 km/h. For -250mm (on hard ground), clearance speed is 300 meters/hour, in soft ground like sand, the speed is between 500 and 600 m/h. It can clear a 120-meter lane in 10 minutes. With the flail system forward (but not lowered into operational position), the Keiler can travel at 21 km/h (13 mph).

Close up photo of the Keiler’s flail operating at full speed. In operation, the flail kicks up a tremendous amount of debris that often results in the top deck being covered in a thick layer of muck. Photo: Ralph Zwilling

An impressive photo of the Keiler detonating a buried mine during a joint German and Dutch training exercise in 2014. Photo: Alexander Koerner

Lane Marker System

Located centrally on the rear of the Keiler is a large box. The box is the vehicle’s lane marking system known as ‘CLAMS’ or ‘Clear Lane Marking System’. Designed and produced by Israeli Military Industries (IMI), this system can drop markers down the center of a cleared lane automatically or manually every 6, 12, 24, 36 or 48m. The markers consist of round metal discs painted white, with a sprung red square on top. There is a clip on the back of the square that can accommodate a glow stick if operating in low visibility or darkness.

The ‘CLAMS’ marker system at the rear of the Keiler. Note also, on the air intakes, the stowage positions for spare track links and rods for the ground level measuring system. This is a pre-track upgrade Keiler, denoted by the fact the original American tracks are installed. Photo: Ralph Zwilling

Crew Positions

Driver

The Keiler is operated by a small crew of just two personnel, consisting of the Driver and Commander. Up until 2004, the original Driver’s hatch from the M48 was retained. It was found that this hatch was not strong enough to stand up to overpressure caused by a mine exploding on top of it. As such, it was replaced by a purpose-built detonation proof hatch. The protective overhang that extends forward from the flat upper hull is in place to stop soil and debris kicked up by the flail accumulating on top of the hatch.

The driver’s position at the front of the vehicle. Note the retractable shield on the bow is in the raised position. The ladder on the right was part of the 2015 upgrade which saw the addition of a ‘safe climbing kit. Photo: Ralph Zwilling

In mine-clearing operations, the driver operates almost blind due to the amount of debris kicked up by the whirling flail. The three vision blocks around his head become useless, as such a gyroscope was installed on the right of the steering wheel. There is a marker that shows forward direction and indicates when the vehicle is veering off course. The driver corrects direction with corresponding movements of the steering wheel. One of the three periscopes can be replaced with a BiV night vision device.

Commander

The Commander’s position is located in the middle of the vehicle, slightly off center to the right of the hull. His position is topped off with a cupola with eight periscopes installed – like the driver, one can be replaced with a BiV night sight. On the right of his position are the controls for the 76mm smoke launchers. The Commander is in overall charge of the mine clearing equipment. The controls for the hydraulics are controlled by the Commander’s operator panel, found in his position.

The commander’s position atop the Keiler. The roof is covered in debris thrown up by the flailing process. Photo: Tankograd Publishing

Due to the direction the flail rotates in, the roof of the Keiler often becomes covered in a deep layer of whatever muck and mire the vehicle happens to be carving through. As such, both crew members will often exit the vehicle through the Driver’s hatch to stop dirt and debris falling into the Commander’s position.

Operation

Before the Keiler even approaches the area that needs to be swept, a good deal of preparation has to take place at a safe location. First, the flail is unbolted from the travel lock. Next, the Commander, using his control panel, rotates the flail equipment forward from the travel position so it is aligned in front of the vehicle. The ratchet straps are then removed from the flail chains which are then unfurled from the rotating shaft. The detachable ground level measuring rods are then installed on each end of the clearing shaft (If they haven’t been left on from a previous job). The headlights – all German tanks are required by law to have these, as well as tail lights and wing-mirrors for driving on public roads – are removed from the fenders over the idler wheels at the front of the Keiler to prevent them from being damaged.

A pre-2015 upgrade Keiler traveling at speed. The driver is operating head out. Photo: SOURCE

Once preparation is complete, the Keiler will drive to the area of clearing. Once there, the Commander will lower the flail into clearing position and order the Driver forwards at whichever clearing speed is required. In mine-clearing operations, it could be said that the Keiler gains a third crew member in the form of an outside observer. As the crew operates mostly blind due to the kick up from the flail, a Troop Commander, stationed at a safe distance from the clearing area, guides the vehicle by radio communication to the Commander, who then relays the commands to the Driver.

Troops of the Bundeswehr stand before a Marder 1A3 (I) and Keiler. Photo: MDR

Service

In its 22 years of service, the Keiler has been deployed to various countries with the German Army. In the late 1990s, the German Army took part in NATO’s Implementation Force (IFOR) Bosnia-Herzegovina during the Bosnian War, codenamed ‘Operation Joint Endeavor’. They remained here for Stabilisation Force (SFOR) operations as well.

Keiler in operation in Butmire, Bosnia-Herzegovina, in 1997. Photo: Wikimedia Commons

Unfortunately, further details about its deployments are scarce. Recently in 2015, the Keiler was part of the German contingent that took part in NATO’s Trident Juncture ‘15. The exercises took place in San Gregorio in Spain.

Keiler in operation in Trident Juncture ‘15 in San Gregorio, Spain. Photo: Allied Joint Force Command Brunssum

The Keiler is projected to remain in service with the German Army for the foreseeable future and remains one of the most technically advanced and reliable mine clearing vehicles in the world today. It is part of a vast arsenal of Mine Clearing vehicles in service, such as the Wiesel 1 based Detektorfahrzeug Route Clearance System (DetFzg RCSys) and Manipulatorfahrzeug Mine Wolf MW240 (MFzg RCSys). One of the Keilers that was deployed to, and operated in, Bosnia as part of IFOR can be found in the Deutsches Panzermuseum, Munster. It is in running condition and is often part of the Museum’s displays.

The IFOR veteran MiRPz Keiler preserved in the Deutsches Panzermuseum, Munster. Photo: Public Domain

Specifications (Post 2015 upgrade) |

|

| Dimensions (L-W-H) | 6.4 x 3.63 x 3.08 meters |

| Total weight, battle ready | 56 tonnes |

| Crew | 2 (Commander, Driver) |

| Propulsion | MTU MB 871 Ka-501 liquid cooled, 8-cylinder, turbocharged diesel, 960 – 1112hp |

| Transmission | Renk 6 speed (4 forward + 2 reverse) |

| Speed | Travel Mode (forward): 48 km/h (30 mph) Travel Mode (reverse): 25 km/h (15 mph) Flail Deployed: 21 km/h (13 mph) Clearence Mode: 2 – 4 km/h (1.2 – 2.4 mph) |

| Suspensions | Torsion bars |

| Equipment | Mine Flial, 400 rpm, twenty-four 25kg elements impacting at 200 km/h, 98-100% clearence IMI CLAMS (Clear Lane Marking System) marker system 76mm Smoke grenade launchers |

| Armor | 110 mm (hull front) |

| Total Production | 24 |

Sources

Ralph Zwilling, Minenräumfahrzeuge: Mine-clearing Vehicles from the Keiler to the German Route Clearance System, Tankograd Publishing

Ralph Zwilling, Tankograd In Detail, Fast Track #15: Keiler, Tankograd Publishing

www.rheinmetall-defence.com

www.military-today.com

tag-der-bundeswehr.de

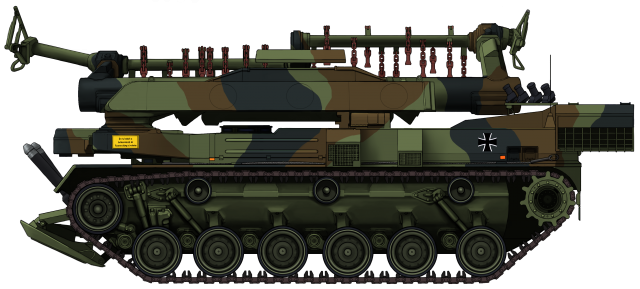

The Minenräumpaner Keiler in travel configuration. In this mode, the entire flail unit is stored horizontally along the length of the vehicle. The protective shield on the bow is also raised so it is clear of the ground while the vehicle is in motion.

TheMiRPz Keiler in mine clearing mode with flail assembly deployed. Note the flail chains, each equipped with 25kg ‘Elephant’s foot’. The rods at each end of the assembly are for measuring ground level. The bow shield is also deployed.

Both of these illustrations were produced by Ardhya Anargha, funded by our Patreon campaign.

2 replies on “Minenräumpanzer Keiler”

Amazing Article! Thanks!

trully interesting vehicle. is it still in operation?