Republic of South Africa (2018)

Republic of South Africa (2018)

Infantry Combat Vehicle – 22 Built

“Badger” – The Modern African Bushfighter

South Africa has a long tradition of designing highly mobile wheeled armored vehicles such as the Casspir, Ratel, Rhino and Rooikat. The terrain and climate in the region, as well as the strategic defence needs of South Africa, require a highly mobile Infantry Fighting Vehicle (ICV) able to travel large distances and fulfil a wide variety of roles. The Badger ICV adopts its name from its predecessor, the “Ratel”. This animal, despite its small size, is a fierce creature that can sustain a large amount of physical damage as well as inflict it with its long claws. The Badger is therefore well named as its modern armament, enhanced protection, and vastly improved mobility over its predecessor the Ratel make it a formidable opponent. It is designed and produced at a time when South Africa, as a fully-fledged democracy, is undertaking more peacekeeping responsibilities on the African continent. While its neighbours still rely heavily on Soviet-designed equipment, South Africa chose to continue its tradition of self-reliance by making use of more than 70% local content for the Badger.

Development

With the venerable Ratel ICV passing 46 years of service in 2022, the need for a more modern ICV is seen as paramount. Having formed the backbone of South African mechanised battalions for 13 years during the South African Border War (1968-1989) and continuing to serve until the present day, the Ratel is starting to show its age. Shortages of dedicated parts make logistics very difficult, resulting in cannibalization of surplus vehicles.

The need for a modern ICV was already laid down in 1995 with the writing up of the required operational capability by the South African National Defence Force (SANDF). This was subsequently approved and followed by the staff target and staff requirement, which consists of a functional user requirement and logistical user requirement. In essence, a wish list of capabilities. The Armaments Corporation of South Africa SOC Ltd (ARMSCOR) was tasked with translating these requirements into technical engineering terms. During the following three years, the SANDF decided to prioritise the modernisation of its Navy (4 Valour class frigates and 3 x 209 Class diesel submarines) and Air Force (26 Gripen C/D and 24 Hawk 120). Subsequently, the Army had to make do with what it had for at least another ten years.

By early 2005, eight South African and four international defence contractors were asked to submit proposals and budgets for a new ICV under the code name “Project Hoefyster (Horseshoe)”. Only one bid was received from a consortium which consisted of the Finnish Patria and its part-owner, EADS (European Aeronautic, Defence and Space Company), Denel, OMC (Olifant Manufacturing Company) and Land Mobility Technologies (LMT). The proposed vehicle was the Patria’s 8×8 Armored Modular Vehicle (AMV), which would be redesigned for southern African battle space by LMT. OMC would manufacture the hulls and Denel the turrets and main armaments. The approved budget for the project was around US$780 million.

In May 2007, Denel Land Systems (DLS) was contracted to do the internal fits and supply one prototype of each of the envisaged five variants using the Patria hulls that arrived in South Africa. Each was evaluated and accepted by the SANDF which led to 22 pre-production vehicles being built by Patria in Finland. In late 2010, the SANDF awarded DLS a further contract to develop Badger ICV products. The then Minister of Defence approved “Project Hoefyster” in 2013 after the initial development phase was complete. The original order called for 264 vehicles but was later reduced to 238. The number of vehicles was then changed to 244 ICVs after increasing advance payments to the industry. The 244 ICVs would have consisted of 97 Section, 14 Fire support, 41 Mortar, 70 Command, 14 Missile, and 8 Ambulance vehicles.

The Badger will be primarily used by 1 South African Infantry Battalion (SAI) based in Bloemfontein and 8 SAI situated in Upington. The principal tasks of the Badger are variant-specific and include troop transport, fire support, anti-armor, command and control, and medical transport.

The first platoon of Badgers underwent operational testing and evaluations at General de Wet Training Center (De Brug) just outside Bloemfontein in 2018.

On 16 February 2022, the Armaments Company of South Africa (ARMSCOR) recommended the cancellation of the project due to Denel’s lack of industrial and technical capability in manufacturing it. The monies that would have been recovered would have amounted to some R1.5 Billion rand (US$ 100 Million).

During February 2024 ARMSCOR briefed the Parliament’s Portfolio Committee on Defence and Military Veterans that Denel`s financial woes, exodus of key personnel and deviation of specifications resulted in a devastating capability loss which stalled the project in 2019. It was agreed that Badger production quantities would be reduced from the originally planned three battalions to one battalion consisting of 88 vehicles.

Furthermore, ARMSCOR is studying the possibility of extending the service life of the Ratel IFV. The most likely contender would be the OTT Ratel Service Life Extention Program (SLEP) project.

Design features

The design, development and production of the Badger were undertaken due to the need for a more modern ICV to replace the Ratel presently in service with the SANDF. The Badger is characterized by eight big wheels, mobility, bush-breaking ability, and versatility as a weapons platform which would have been well adapted for its role as a modern ICV in the Southern African battle space.

Mobility

The African battle space favours a wheeled configuration, which makes the Badger the perfect candidate for its role as an ICV. The Badger makes use of an automatic ZF gearbox with seven forward and one reverse gear with the option for the driver to also change gears manually if required. The Badger can ford 1.2 m of water without preparation and has 400 mm of ground clearance. It is powered by a Scania fuel-injected diesel engine which produces 543 hp @ 2100 rpm and provides a 20 hp/t ratio. This horsepower-to-weight ratio allows the Badger to accelerate from 0-60 km/h (0-37.2 mph) in under 20 seconds and 60-100 km/h (37-62 mph) in under 40 seconds, and achieve a top speed of 104 km/h (64 mph). The Badger retains 70% mobility with the loss of one wheel and 30% with the loss of two wheels. The wheels feature a central tyre inflation system. It can cross a 2 m trench at a 3km/h crawl, can climb a gradient of 60%, and has a side slope rating of 30%. The suspension system makes use of hydro-pneumatic struts which allow for true independent wheel movement over rough terrain, thereby dramatically increasing the stability of the vehicle and ensuring a smoother ride for the occupants (see Mobility track demonstration, AAD 2016 video below at 0.37 sec). All wheels are equipped with ABS brakes. The auxiliary power unit (APU) allows all onboard systems to remain powered even if the engine is switched off.

Endurance and logistics

The fuel capacity of the Badger is 450 litres (118.8 US gallons) which allows it to travel 1000 km (621 mi) on the road and 750 km (311 mi) off-road. 190 litres (50.2 US gallons) are stored in the left fuel tank and 230 litres (60.7 US gallons) in the right one, while another 27 litres (7.1 US gallons) are located in the transfer tank. The Badger is fitted with a mix of up to 2 x VHF, and 3 x HF tactical radios which allow for reliable inter-crew and multivehicle communication. This command and control system enhances the ICV`s force multiplier effect on the battlefield. The Badger features four built-in drinking water tanks with a total capacity of 130 litres (34.3 US gallons).

Vehicle layout

Most Badgers carry a standard complement of four crew members, consisting of the troop commander, vehicle commander, gunner, and driver. The vehicle commander’s station is located on the left side and the gunner’s station is on the right of the turret. The troop commander is positioned behind the driver who is seated in the forward left side of the hull. Each station in the turret has six vision blocks which provide a 270-degree field of view. The vehicle commander has at his disposal a day video sight that offers a stabilised 360-degree capability. Both the vehicle commander and the gunner have a 360-degree situational awareness through episcopes and multi-function flat-panel video displays. Additionally, the vehicle commander has the ability, via the video sight, to override the gunner’s control and slave the main gun onto a target. The gunner’s station is fitted with an x8 day and night, thermal sight periscope as well as an auxiliary gunner sight with direct view optics with aiming reticules. Entry and exit for the former and latter are through the gunner’s and vehicle commander’s cupola. In an emergency, the gunner and vehicle commander can escape through the rear of the vehicle. The driver’s station is located on the front left of the hull and is accessible through the fighting compartment or a single-piece hatch above the driver’s station. The driver’s station is adjustable and features three periscopes for enhanced visibility and situational awareness. The central periscope can be substituted with a passive night driving periscope allowing full day/night capability. The driver can make use of compressed air to clean his periscopes while buttoned-up, a feature particularly useful in the dusty climates in which the Badger will operate. The driver makes use of a power-assisted steering wheel to drive while acceleration and braking are controlled with foot pedals.

The rear compartment has seating space for passengers the number of which is variant-specific. The Badgers crew and passenger compartment feature an air conditioning unit, which helps reduce crew and passenger fatigue. The passenger seats face inward and are fitted to a frame that is attached to the hull in such a way that should a mine detonate under a wheel or hull the minimum amount of mine blast energy reaches the passenger seats, thereby reducing the possibility of spinal injury. Additionally, each seat is fitted with a footrest which allows the passenger across from the seat to rest their feet off the floor, also to reduce the possibility of injury should a mine be detonated. The Badger is fitted with several hulls encased, an all-around camera video system for enhanced situational awareness. The troop compartment is equipped with several monitors displaying the camera views and a dedicated section leader monitor for planning and presentation purposes. The hydraulically operated rear door was designed in South Africa and doubles as a weapons and equipment rack that can hold entrenching tools, a light machine gun (LMG), a 40mm six-round grenade launcher, RPG-7, 60mm patrol mortar and ammunition for the aforementioned weapons. The advantage of such an arrangement is that it frees up the troop compartment from unnecessary clutter and provides quick access to troops disembarking from the rear. Entry and exit from the rear door are made easier by a step that deploys mechanically as the door opens and retracts when the rear door closes.

Main gun

The Badger makes use of the Light Combat Turret (LCT) which forms part of a Modular Infantry Combat Turret (MICT) family developed by Denel as part of the New Generation Infantry Combat Vehicle (NGICV) programme for the SANDF. The turret family is built around the Fighting Compartment Module (FMC) principle which allows various weapons and sighting systems to be integrated with ease. Such a design vastly reduces logistical requirements, operational costs, training time and ensures maximum commonality and re-use of components within the modules. Both the Section variant and the Fire Support variant make use of the LCT-30 turret which can make a full 360-degree rotation in 13 seconds. The Mortar variant is equipped with the LCT-60 while the command variant is equipped with the LCT-12.7, and the Missile variant uses the LCT-Missile turret.

The Section variant is armed with a Denel 30 mm dual-feed linkless Camgun (EMAK 30) which can engage targets effectively at 4000 m. The Camgun features a double baffle muzzle brake and has a single recoil mechanism. Rapid-fire consists of a 3-round burst mode which provides 60 rounds per minute. Empty cartridges are ejected on the left side of the turret. The section variant carries 400 x 30 mm cannon rounds. The rounds carried consist of Armor-Piercing-Fin-Stabilised-Discarding-Sabot (APFSDS) for use against armored targets and Semi-Armor-Piercing-High-Explosive-Incendiary (SAPHEI) for use against soft targets. Literature searches reveal that modern 30 mm cannon rounds such as the APFSDS have a muzzle velocity of 1430 m/s and can penetrate < 100 mm of Rolled Homogeneous Armor (RHA) at 1000 m. This is significant considering that Infantry Fighting Vehicles (IFV) such as the BMP-2 and BMP-3 only have 33 mm and 35 mm of frontal armor respectively. Furthermore, this means that the Badger Section variant is capable of knocking out T-55, T-62 and T-72 Main Battle Tanks (MBT) found in the region from the sides and rear from range. It should, however, be stressed that the Section variant is not supposed to engage MBT`s directly. The SAPHEI has a muzzle velocity of 1100 m/s and can penetrate 30 mm of steel plate at 30 degrees at 200 m.

All but the Ambulance variant is armed with a co-axial 7.62 mm belt-fed machine gun with a total of 4000 rounds (20 belts of 200 rounds each). The vehicle commander has at his disposal a stabilised panoramic sight and a primary stabilised main sight that can track targets automatically. All variants have a day/night sight capability as standard with some variation of the fire-control system which is variant-specific.

Fire Control System

The Badger is equipped with the FDS digital fire control system which receives information from a laser rangefinder and accurately places rounds on target with the main gun. The laser rangefinder is accurate to within 5 m at 10 km. The variations are automatically calculated and compensated according to the ammunition selected by the gunner. The fire control system allows the gunner to select a target in less than two seconds. The fire solution is given allowing the gunner to fire on target which adjusts the main gun’s auto lay aim. The commander can override the gunner’s aim with the flip of a switch to put the main cannon on target. This effectively provides the Badger with hunter-killer capability. The digital fire control system allows hits on a moving target while the Badger is on the move itself by adjusting the main gun’s aim after taking into account the distance to the target, the relative speeds and relative direction, thereby maximising first-round hit probability. The single-shot hit probability while static at a 2.4 m x 2.4 m target at 2000 m is greater than 65%.

Protection

The Badger is based on the Finnish Patria Armored Modular Vehicle (AMV). Unlike its European counterpart, the Badger has numerous modifications such as dedicated bush protection to enhance its durability for use in the African bush. The Badger features a dual hull design to enhance survivability against kinetic and high explosive anti-tank (HEAT) projectiles. The total thickness of the outer/inner hull and add-on armor package and composition thereof are classified. The outer hull (which can be removed) functions as a first-line defence against light and medium arms. This is followed by an empty space of classified width which can act either as spaced armor or can be fitted with an add-on armor package developed by Armscor`s Armor Technology Institute. The add-on armor over the frontal arc is left in place during peacetime whereas the left and right sides add-on armor is removed. Lastly is the inner hull which serves as the last line of defence. The inner hull is fitted with an anti-spall lining to reduce crew vulnerability to fragments in case of penetration. It was reported from Afghanistan, where the Badger’s cousin the Patria was deployed, that two such vehicles equipped with add-on armor packages, survived direct hits from RPG-7s which did not penetrate the inner hull. It is unclear what types the RPG rounds were. The Badger is protected against 30 mm APFSDS rounds over the frontal arch and 23 mm Armor Piercing (AP) rounds around the remaining hull. The roof is rated against heavy artillery blast and fragmentation.

Due to the prevalence of anti-tank (AT) and anti-personnel mines in Sub-Saharan Africa, the Badger features a flat bottom mine-protected hull (not found in the Patria) which absorbs the blast and shock produced by a mine detonation. The technology was developed by Land Mobility Technology (LMT) and offers protection against the equivalent of a 6 kg mine anywhere under the hull.

The Badger features two automatic fire suppression systems, one for the engine and the other for the crew/troop compartment. The system can also be engaged manually. The Badger is fully Nuclear, Biological and Chemical (NBC) capable as it comes standard with an overpressure system. Two banks of two smoke grenade launchers are located on the roof of the turret, behind the commander and gunner’s station to protect them from damage when “bundu bashing” (driving through dense vegetation). The hull headlamps are encased in the hull, and an armored screen was added to protect them from damage while “bundu bashing”. A recent addition to all the Badger variants is a guide rail/cage on the turret, the main purpose of which is to guide branches over the commander’s sight to avoid damage to it.

Variants

There are six variants of the Badger, of which five are armed, namely the Section variant (30 mm), Fire support variant (30 mm), Mortar variant (60 mm), Command variant (12.7 mm) and Missile variant (Ingwe). The Ambulance variant is not armed.

Section variant

The Section variant is armed with a Denel 30 mm dual-feed linkless Cam Gun (EMAK 30) which can engage targets up to 4000 m when firing one round at a time. Rapid-fire consists of 3-round bursts. The Section variant carries 400, 30 x 173mm rounds. The rear compartment of the Section variant has seating space for four passengers on the left and three passengers on the right.

Fire support variant

The Fire support variant carries the same main armament as the Section variant but has additional main armament ammunition which is kept in storage racks on the right-hand side of the passenger compartment. Seating in the passenger compartment is limited to two for use by a dedicated two-man anti-tank team.

Mortar variant

The primary purpose of the Mortar variant is to supply indirect fire support to attacking forces. It is equipped with a 60 mm DLS breech-loading, water-cooled mortar which can engage targets directly at 1500 m in line of sight or 6200 m indirectly. The mortar variant carries 256 x 60 mm bombs and has a firing rate of 6 bombs per minute (one every 10 seconds) and an accuracy of 2.4 m x 2.4 m at 1500 m. It has a 40% better lethality and effectiveness than the old 81mm mortar bombs. The variant has four crew members, namely the vehicle commander, gunner, driver, and technician. The bombs are kept in bin racks on either side of the rear compartment with the technician’s seat on the left.

Command variant

The Command variant is armed with a primary 12.7 mm machine gun which allows more room for Command and Control (C&C) equipment and personnel. The command variant carries 1200 x 12.7 mm rounds. This variant has a standard crew of three (driver, vehicle commander, and gunner) and two to three communication staff in the rear.

Missile variant

The Missile variant is armed with the Denel Dynamics ‘Ingwe’ (Leopard) laser-guided, jam-resistant, beam-riding missile which has an effective engagement range of over 5000 m. The Ingwe has a tandem warhead that can defeat Explosive Reactive Armor (ERA) and can penetrate up to 1000 mm of RHA. On either side of the turret is a missile launcher system, which accommodates two missiles. When not in use, the missile launcher reverts to a 45-degree nose-down sloped position behind a protective plate to protect the launcher from small arms fire and possible damage when “bundu bashing”. When a target is to be engaged, the missile launcher’s nose rises 45 degrees up to a level position, from where the missile can be fired. A total of 12 missiles are carried in the rear compartment racks on either side of the hull. The Missile variant carries a driver, vehicle commander, gunner and loader. The missile launchers are rearmed from within the vehicle via guide rails. Each Ingwe weighs 34 kg and requires two people to load.

Ambulance variant

The Ambulance variant has a crew complement of 3 which consists of a driver and two medical personnel. The Ambulance variant has no turret and instead has a higher roof than the other variants. It features an effective patient handling system allowing for the minimum effort of moving patients using rails and a winch system. The rear compartment is better-lit than the other variants. Three patients lying down can be carried at a time or two patients lying down and four seated.

Conclusion

The Badger was set to be the first new ICV in the SANDF inventory since the Ratel was introduced in 1975. The Badger would be one of the best-protected vehicles of its class in the world. This, combined with its mobility and firepower, makes for a formidable adversary. As such, the Badger would have been a worthy successor and a vast improvement over its predecessor, the Ratel. When compared to other modern wheeled ICV`s such as the MOWAG Piranha, Boxer and French IFV’ the Badger would have been much more cost-effective. Ironically Project Hoefyster was set as one of Denels flagship projects will possibly also lead to the final death blow of the once-mighty South African defence company, when creditors come knocking.

Badger Section variant specifications |

|

| Dimensions (hull) (l-w-h): | 8.01 m (26.3 ft.) – 3.44 m (11.3ft.) – 2.83 m (9.28 ft.) |

| Total weight, battle-ready | 28 Tons |

| Crew | 4 crew + 7 troops |

| Propulsion | Scania fuel-injected diesel engine which produces 543 hp @ 2100 rpm. (21.7 hp/t). |

| Suspension | Hydropneumatic struts |

| Top speed road / off-road | 104 km/h (64 mph) / 60 km/h (37 mph) |

| Range road / off-road / sand | 1000 km (621 mi) / 750 km (466 mi) |

| Main armament (see notes) Secondary armament | Denel 30 mm linkless Cam Gun (EMAK 30) 1 × 7.62mm co-axial Browning MG |

| Armor | Exact armor thickness classified. The Bader is protected against 30mm APFSDS rounds over the frontal arch and 23mm AP rounds around the remaining hull. The roof is rated against heavy artillery blast and fragmentation. The hull was tested and proven against the 6 kg anti-tank mine. |

| Total Production (Hulls) | 22 |

Badger Videos

Mobility track demonstration, AAD 2016

AAD 2016: Denel Badger Infantry Fighting Vehicle (IFV)

Bibliography

Reynolds, J. 2012. Denel Land Systems Shows GI-30: 30mm Camgun. African Armed Forces Journal, 2:11.

DEFENCEWEB. 2024. Denel concluding Hoefyster development but fewer vehicles to be manufactured. Date of access: 23 Feb. 2024. (LINK)

DEFENCEWEB. 2022. Denel unable to deliver on Hoefyster contract; Armscor recommends cancellation. Date of access: 17 Feb. 2022. (LINK)

DEFENCEWEB. 2017. First locally produced pre-production Badger expected later this year. Date of access: 5 May. 2018. (LINK)

DENEL. 2018. ADVANCED MODULAR INFANTRY COMBAT TURRET. Date of access: 22 Apr. 2018. (PDF)

Camp, S. & Heitman, H.R. 2014. Surviving the ride: A pictorial history of South African manufactured mine protected vehicles. Pinetown, South Africa: 30° South Publishers

GLOBAL SECURITY.ORG. 2016. Hoefyster (Horseshoe) / Badger. Date of access: 4 May. 2018. (LINK)

MILITARY-TODAY. 2014. Badger Infantry Fighting Vehicle. Date of access: 17 Apr. 2017. (LINK)

Martin, G. 2016. Defence Equipment for South Africa. Military Technology, 40(9): 64-69.

NAMMO. 2018. Nammo ammunition handbook. 5th Ed. Date of access: 15 Apr. 2018. (PDF)

Smit, A. 2018. Interview with Badger, project manager Denel. Date 9 Feb. 2018.

VEG Magazine. 2005. Die vervaning van `n legende: Projek Hoefyster. Issue 8. Victor Logistics.

Help support tank’s encyclopedia with the official Denel’s Badger poster !

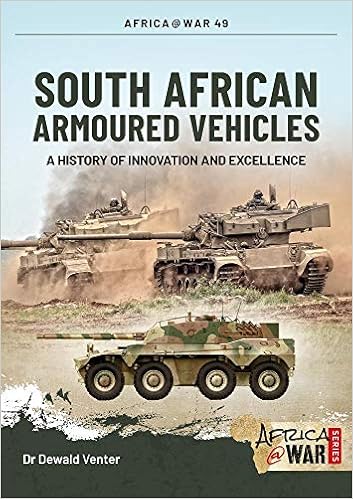

South African Armoured Fighting Vehicles: A History of Innovation and Excellence, 1960-2020 (Africa@War)

During the Cold War, Africa became a prime location for proxy wars between the East and the West. Against the backdrop of a steep rise in liberation movements backed by Eastern Bloc communist countries such as Cuba and the Soviet Union, southern Africa saw one of the most intense wars ever fought on the continent.

Subjected to international sanctions due to its policies of racial segregation, known as Apartheid, South Africa was cut off from sources of major arms systems from 1977. Over the following years, the country became involved in the war in Angola, which gradually grew in ferocity and converted into a conventional war. With the available equipment being ill-suited to the local, hot, dry and dusty climate, and confronted with the omnipresent threat of land mines, the South Africans began researching and developing their own, often groundbreaking and innovative weapon systems.

The results were designs for some of the most robust armored vehicles produced anywhere in the world for their time, and highly influential for further development in multiple fields ever since. Decades later, the lineage of some of the vehicles in question can still be seen on many of battlefields around the world, especially those riddled by land mines and so-called improvised explosive devices.

South African Armoured Fighting Vehicles takes an in-depth look at 13 iconic South African armored vehicles. The development of each vehicle is rolled out in the form of a breakdown of their main features, layout and design, equipment, capabilities, variants and service experiences. Illustrated by over 100 authentic photographs and more than two dozen custom-drawn color profiles, this volume provides an exclusive and indispensable source of reference.

12 replies on “Badger”

Seems like a waste to squander a mere 60mm mortar on our limited fleet of armoured vehicles. Referring to my uneducated guess that such a small support weapon is better left to infantry borne troops. Nice addition none the less.

Sometimes bigger isn’t always better, a smaller calibre weapon can be beneficial on an AFV for a couple of reasons.

1.Smaller calibre weapons allow for more ammunition to be carried per vehicle, which can be a desirable trade off if the vehicle is expected to provided long term fire support without having to resupply.

2. Smaller rounds can be more manageable in the close confines of an AFV, especially in designs intended to be modular (ie multi role tracked/wheeled IFV designs) where the size of the turret is significantly smaller than a tank and space for a dedicated loader in the crew is restricted or absent

3. Smaller rounds have less mass and less recoil, this can allow for a more rapid firing weapon which can allow a single vehicle to put more frequent rounds on target while still remaining accurate. This can be especially important if these vehicles are dispersed throughout the force (ie one mortar vehicle per group of regular APCs/IFVs) instead of grouped in a dedicated indirect fire support group.

4.Many of these smaller calibre ‘mortars’ mounted on AFVs can also be used in a direct fire role, essentially making it a 60mm low velocity gun

-TE Moderator

Interestingly enough the new generation of 60 mm has 40% better lethality and effectiveness than the old 81mm mortar bombs.

Hello Aspern!

You are indeed correct. I have made some quick corrections and sent this to our Italian expert for a complete redo.

Interesting idea – Hollow Point/HEAT Mortar rounds … Thanks

Hello Dewald, I would like to get into contact with you concerning a book I’m working on. Your input and knowledge on a particular aspect of RSA armoured vehicle engineering would be very much appreciated. We can correspond further by e-mail. Thanks!

Email incoming.

The Ratel 90 played a huge role in the bush war. Would a bigger gun also be considered for the Badger?

Nope.

There are plans to upgrade the Rooikat to 105 if funding ever become available.

So when exactly is the Badger going to completely replace the Ratel in SANDF service?

I’m interested to know if David Bocquelet’s South African armor profile illustrations are available commercially for purchase.