The lightest & fastest western MBT

The Leclerc is recognised by numerous world's defence experts as being certainly in the "top five" of today's best MBTs although its chances to stay so are now reduced due to its age and the arrival of recent and very serious contenders. However as we recall these grades are worthless until the tank is battle-tested against equivalents. These considerations does not diminish the technical achievement done by GIAT with the Leclerc, furthermore when compared to the previous AMX-30.The latter was in effect the product of an early cold war reflexion which emphasised mobility over protection, but the second solved this issue while maintaining in its development the cursor over mobility and firepower. It was the fastest and most expensive tank in the world when entering service in 1991. It must also be noted that the AMX 56 designation, while very popular with the media and many military-oriented websites, is not used in anyway officially.

Early developments

The genesis of the Leclerc can be traced back in the early 1980s, when the AMX-32 was first unveiled, but the overall development for a replacement of the AMX-30 took much longer, already starting when the latter became operational. Retrospectively the AMX-30 is considered woefully under-armored and although the next AMX-32 and AMX-40 partially resolved the problem, it was still largely insufficient even by 1987-88 standards. The development that led to secure the Leclerc program while still favoring active protection through speed and agility, called for a much upgraded and modernized passive protection. This program traduced itself not in an overhauled AMX-30 but a brand new, 4th generation MBT, that took five years to develop from the first computer drawings to the first batch delivery at Roanne.The AMX-32

The AMX-32 was a 1975 project intended for export, and a testbed for some new technologies. It was first publicly revealed in 1982. The two main focuses of the engineers were to improve the protection and enhance the Fire Control System. The frontal armor was multi-layered and claimed to defeat 100 mm AP shells, while the turret was entirely reshaped, all-welded, with three faceted sides and internal compartmentation. Although not composite it was also layered. The traverse engine, electro-hydraulic mechanisms which also provided elevation for the main gun were manufactured by SAMM. The rigid side skirts provided extra protection for the drivetrain and upper tracks. Outside the usual 105 mm main gun, the AMX-32 featured a new smoothbore gun 120 mm CN120-25 G1 capable of firing German APFSDS and other NATO rounds. Secondary armament comprises the same 20 mm Autocannon and a roof-mounted 7.62 mm AA-52 LMG (respectively 38, 480 and 2150 rounds). Some of its features were passed on to the AMX-30B2.

AMX-32 now on display at Saumur tank museum.

The AMX-32 is provided with a COTAS Fire Control System which includes a ballistic computer, passive observation and target positioning devices, and a laser rangefinder. The Commander is given a M-527 Hydro-Stabilized Panorama Sight, an a 8 periscopes on its cupola. The Gunner had a M-581 Telescopic Sight with 10x magnification, directly connected with the laser rangefinder and three periscopes. The DIVT-13A Thomson-CSF Thermal Camera for the main gun provided night combat/low visbility capabilities. The main gun accuracy was also provided by a tilt sensor, a deviation sensor, an optical deflector and tachometers. Although there was no gun stabilization system, first hit capability was estimated 90% at 2 000 m. Mobility was excellent, provided by a HS-110-S2 engine (AMX-30B2) with an ENG-200 hydromechanical transmission. NBC protection, fire extinguishers and intercom were standards. Characteristics and field performances were as follows:

- Combat weight: 40 metric tons

- Dimensions: 6.59 x 3.1 x 2.29 m

- Armament: 105 mm rifled or 120 mm GIAT CN120-25 G1 sb gun, coaxial M-693 20-mm, 7.62 LMG.

- Protection: Layered RHA, stratified turret and hull, 300-350 mm equivalent RHA.

- Engine: 12 cyl diesel Hispano-Suiza HS-110-2-SR 800 hp (820 KW)

- Suspensions: Torsion bars

- Top speed/range: 65 kph (45 kph off-road), 520-530 km/900 liters

- Field perf. Slopes 60°, step 0.9 m, trench 2.9 m, fords 1.3 m to 4 m prep.

The AMX-40

For this next step also aimed both at the export market and internal development, GIAT's engineers almost took a blank page. The prototype was still partly based on the AMX-30B2 and was presented at Eurosatory 1983. Two other prototypes followed in 1984 and one in 1985 (AMX-40E4). As a standard, there was now the smoothbore 120 mm GIAT CN120-25 G1 main gun, but the 20 mm F2 M693 autocannon was now optional. The roof's AA-52 LMG was kept. Ammo respectively comprised 40, 578 and 2170 rounds. The main gun used most of the systems already used on the B2 and AMX-32 including the COTAS FCS. AMX-40 here at Satory.

AMX-40 here at Satory.

The armor and turret design were still layered and slightly better to the one saw on the AMX-32, with perforated and laminated steel protecting against 100 m HEAT/APDS (sabot) rounds, although still well below the protection standards in 1990. The weight rose to 43 metric tons. This was compensated by a radical increase in power that contributed to an even better mobility. The chosen powerplant indeed was the 1,100 hp capable Poyaud V12X diesel engine (820 kW) giving a power/weight ratio of 25.6 hp/ton, and coupled to a German-derived ZF LSG 300 transmission. To house it the hull was slightly enlarged at the rear and a sixth roadwheel was added to compensate for the additional weight. The suspensions system was also revamped, with torsion bars coupled with rotary shock absorbers. Dimensions and weight were slightly superior, but performances were even better, at 70 kph at top speed, and 600 km range for 1300 liters. Specifications and performances are as follows:

- Combat weight: 43.7 metric tons

- Dimensions: 10.04 oa (6.8) x 3.36 x 2.38 m

- Armament: 120 mm GIAT CN120-25 G1 sb gun, coaxial M-693 20mm, 7.62 LMG.

- Protection: Layered RHA, 400-450 mm equivalent RHA.

- Engine: Poyaud V12X diesel 1,100 hp (820 KW)

- Suspensions: Torsion bars + rotary Schock absorbers

- Top speed/range: 70 kph (50 kph off-road), 600 km/1,300 liters

- Field perf. Slopes 60°, step 0.9 m, trench 2.9 m, fords 1.3 m to 4 m prep.

The Engin Principal Prospectif program (1971-80)

First replacement studies for the AMX-30 came as soon as the new MBT entered service in 1964. In 1971, the Engin Principal Prospectif (literally "prospective main craft") pointed the fact the AMX-30 was surpassed by the latest Soviet tanks. The Direction des Armements Terrestres launched the "Engin Futur" program and in 1975 a working committee was established to draw specifications for the new design. There were published in 1977. Once again, France turned to West Germany that already worked on a similar program aimed at replacing the Leopard I. This program was called in Germany Kampfpanzer III, and once in France the "Napoléon I". This was concluded by the signing in February 1980 of a Memorandum of Understanding (MoU) for the joint development but soon, disagreements rose on several points and the two nations decided to pursue their domestic developments in December 1982. The Federal Republic of Germany already signed in December 1974 another MoU with the United States for a joint development program that also failed.

The EPC program or AMX-48 (1983)

The EPC or "Engin Principal de Combat" was a purely national plan for a new MBT after other possibilities were studied and rejected, like a license-built Leopard 2 or M1 Abrams. Prospects to adopt the Merkava were also studied. But once again, the French Army insisted to call for active rather than passive protection for the new tank. The AMX-32 and AMX-40 indeed paved the way for this occurrence, with marginally better armor but excellent mobility. The AMX-40, for example, defined the kind of powerplant that would be adopted for the new AMX design. However, and more importantly it was stated also to achieve the double of the existing protection, well above the 400 mm RHA equivalency, particularly against KE-penetrators and shaped charge projectiles. This was only to be achieved with a 50+ ton class tank and imposed a radical departure over previous designs. By the time the program was already well advanced in 1985, it was though for a partnership with another army to reduce the overall unit cost, and already excellent commercial relations with United Arabs Emirates (which already operated the AMX-30) helped to secure another batch of 400 vehicles, for a total of 860.

The Leclerc development (1984-90)

The "AMX" derived from the old industrial arsenal and industrial complex at Issy-les-Moulineaux and Puteaux. But the program was under supervision of the GIAT armament group (1974) or "Groupement des Industries de l'Armée de Terre", the National Army Industries Group based at Roanne, in the Loire department. The group was responsible for most weapons in service in the French Army before constituting the core of the new NEXTER Defence industry group in 2006. The name "Leclerc" honored the memory of General Philippe Leclerc de Hautecloque that led Free French Forces in Africa and later in Italy, Southern/Eastern France and Southern Germany with the 2nd DB (Armoured Division) and helped to liberate Paris in August 1944.From the drawing boards and computer screens to the first batch delivered in 1990, the development took six years to mature. In 1986, the first six prototypes were delivered by GIAT industries. Tests did not however stopped in 1990 as the first production batch was delivered (four vehicles). Indeed, these vehicles were sent in other countries testing grounds for comparative trials. The next batch of 17 already included many improvements in the turret and hull armour, while the batch 3 integrated corrections in the engine and suspensions and was kept mostly for trials, training, and defining a new doctrine of use. The serie will evolve in the 1atter period (1998-2008) and now counts three series, not including the well-modified UAE version.

Design

Hull & protection

An extremely compact design

As the lightest MBT today, the Leclerc hull is remarkably short, at 9.87 m overall with the gun, 6.88 m hull only. This can be compared to the AMX-40 10.04 m overall length, while their hulls are of almost similar length. However, the Leclerc is wider at 3.60 m compared to 3.36 m (with side skirts) of the latter. It is also taller, at 2.53 versus 2.38 m for the AMX-40, mostly due to the new massive, towering FCS thermal camera. However, the weight of the engine, new armor, and the overall extremely compact design gave a 54.5 ton on the first version, compared to 43.7 tons for the AMX-40: It's more than ten tons heavier for a similar silhouette.The turret looks much shorter than for the AMX-40, but in reality this is deceptive as it is also much wider and overall heavier, jam-packed with equipment, like the two banks of five smoke dischargers blended in the module at the turret rear. At its core this is a two-man design, the crew's loader being replaced by an autoloader, allowing for a more compact turret rear. Its modular construction also includes stealth-designed shapes and a thermal/radar absorbent coating material.

An upgraded protection

The protection is a great leap forward in French tank design, and compared well with other western designs, although still slightly below the 2000s standards. It is entirely modular, composed of welded steel blocks with composite armor of a classified composition, which can be replaced easily for repair or upgrades. The Chobham armor was once considered and rejected as too optimized to defeat hollow charge-weapons whereas the French system is less specialized and was designed to defeat both hollow charge and sabot rounds. The batch 3 or SXXI version armor package introduced in the 2010s includes high-density titanium inserts, tungsten and semi-reactive layers (NERA), fitted on the sides of the turret, as well as ERA blocks. However, as its weight suggests, this protection was at first thought to be less or equivalent to that found the Challenger 2 or M1A2 Abrams, but be compared to the M1A1HA in its latest version. A live test showed survivability to a DM43 round fired from 2,000 m.In addition, the active protection system is designed by Nexter and Lacroix Tous Artifices. The GALIX active combat vehicle protection system includes two banks of five 80 mm dischargers, firing smoke grenades, infrared screening rounds decoys or anti-personnel grenades, fired from inside the module. The entire block is modular and could be replaced easily, and the rounds could be automatically selected and loaded from the internal central combat console. In addition, more recently, NEXTER provided the KBCM defensive aids suite which comprises a laser and missile warner and an infrared jammer, integrated into the FINDERS BMS (see later). Crew protection includes automatic fire extinguishers and a full NBC lining and a slight overpressure inside the crew compartment as the tank is entirely sealed off.

The AZUR Urban kit

In June 2006, Nexter delivered a kit optimised for urban operations, consisting in additional side skirts of composite material, BAR armor on the hull and turret rear to protect against RPGs, and special engine deck armored deflectors to protect the engine against hand-thrown petrol bombs. It is completed by an extra remotely operated 7.62 mm AA-52 light machine with day/night sight, a wireless communication system with infantry, a rear-driving audio alert, a close panoramic observation system, rear extra storage bins replacing the fuel drums, and a new electrical interface for civilian hardware. By early 2011, the International Golden Group was contracted to deliver this kit for the UAE Armed Forces but it was also tested by French tanks.Armament

Main tank gun

Since the emphasis was given to mobility and armament, the Leclerc punches slightly over its weight. The new smoothbore GIAT CN120-26/52 120 mm is 52-caliber long and is fitted with a thermal sleeve and muzzle reference system. This barrel length is also slightly above western tank standards (44 calibers are most common) which gave better muzzle velocity (1,790 m/s muzzle velocity for the APFSDS), at least until the introduction of the L55 Challenger. The fumes are not exhausted by a bore evacuator but calls for an automatic compressed-air fume extraction system instead.The rate of fire is enhanced by the use of an entirely electrical aiming system, dual-axis stabilizer and an automatic loading system giving 12 rounds per minute on average. Ammunitions are fully NATO standards compliant (compatible with Leopard 2 and M1 Abrams ordnance), and includes the OFL 120 F1-A APFSDS (armour-piercing fin-stabilised discarding sabot), OECC 120 F1 HEAT (high-explosive anti-tank), OE 120 G1 HE, OFLX 120 G and BSCC 120 F1 for training and two replicas for handling training.

However, like most autoloaders, it cannot change ammunition types once a round has been loaded. Due to the autoloader with preselector and a full stabilization unit (both optics and gun) cross-country fire-on-the-move against mobile targets is largely enhanced, with a 90% first hit capability at 4000 m, traveling at 50 kph. There is always one ready to fire round in the chamber, 22 rounds of ready-to-use ammunition carried inside the autoloader magazine, for 40 rounds in total, the remainder 18 being stored inside a revolver type barillet located in right hull front, loaded with a simple hand crank. Spent cartridges are automatically ejected through a turret rear port.

Secondary weapon

The tank is armed with a US-designed 12.7 mm M2HB heavy machine gun which is co-axial with the main gun, supplied with 1100 rounds. This feature is shared with the Abrams, although on the latter this weapon is roof-mounted. It also has a roof-mounted 7.62 mm AA-52 anti-aircraft gun, remotely controlled, supplied with 3000 rounds. In addition, a second remotely-operated AA-52 can be fitted on the turret as part of the AZUR ("Action en Zone Urbaine" or "Urban zone Action") urban combat kit upgrade.Crew

The driver is located in the hull front left. He can access the tank through a small hatch opening to the left. Its compartment itself is roomy and comfortable, with a fully adjustable seat. He could see through three large periscopes mounted in the hatch, equipped with de-icing while the center one had, in addition, a cleaning system and displays the turret direction, completed by a right small mirror. Steering is operated by a multi-functional wheel, with a right-placed gear shifting, and left instrumental panel which displays speed, engine rpm, fuel capacity and temperature. A larger control panel contains switches for the engine, fuel cells and other systems.The tank commander and gunner take place in the front section of the turret, but in a lower position deep inside the vehicle at their own battle stations. The tank commander is seated to the right and can observe the surroundings through 7 periscopes and the HL-70 binocular Panoramic sight (day channel X2.5 and X10 magnification, a night channel with X2.5 magnification). The gunner is located to his left and is given a SAGEM HL-60 primary sight (later HS-70) with a day channel X3.3 and X10, and night channel offering X3, X6, X10 and X20 magnifications. These sights are also equipped with a semi-auto tracker for target acquisition. In addition, the gunner has a SAVAN 20 stabilised sight, developed by SAGEM. Both the TC and Gunner can traverse the turret through a horizontal control handle.

Respectively, the gunner's and Tank commander respective positions seen from above.

Fire Control and Battle Management Systems

The Leclerc FCS (Fire Control System) allows the tank to engage and destroy up to 12 targets in less than one minute, when cruising off-road at full speed, in very low visibility or at night and at distances up to 3000+ m and with a first hit probability around 95% in optimal conditions. This comprised the gunner and commander sights, laser range finder of the Nd:YAG type (1.06 µm). The combination of the gunner's primary sight and commanders panoramic sight allows the Leclerc to operate in a hunter-killer mode, and the digital fire control system can be operated independently by the gunner or the commander. It offers real-time integrated imaging and sensor's data from all of the turret.Nexter's systems FINDERS battle management system (BMS) is ensuring fast information, navigation, decision, and reporting system included a color map displaying the positions of the tank, allied, hostile and designated targets with real time updates. By 2008, the ICONE TIS (terminal information system) BMS is gradually retrofitted on the S2 and SXXI series for all operational Leclercs, with a digital communication system that integrates data from other tanks and upper levels of command. Also called ICONE (ergonomic communications and navigation interface), it has been developed together with EADS Defense Electronics Systems. It comprised better digitized data exchanges, a more precise tactical situation awareness and an enhanced HD background map graphic displaying real time orders.

Mobility

The raison d'être of the new Leclerc design was its active protection, embodied by a top speed, off-road speed, and in general excellent mobility characteristics. In recent years comparative trials showed the Leclerc's performances were above those of the current MBTs of the time, including the Leopard 2, Challenger and Abrams, both in terms of speed and acceleration. This was not achieved by raw engine power but rather through small dimensions and thus limited weight. In this respect, only Soviet tanks of the contemporaryT-64/72/90 types are comparable, although the latter have a much lower profile. For the first version planned back in 1986 the V12X Poyaud diesel engine previously tried on the AMX-40 design was once considered, but due to the new weight class and problems encountered, quickly dismissed. Instead, it was sourced abroad, giving the SACM V8X-1500 1,500 hp Hyperbar engine. SACM is a subsidiary or the Finnish company Wärtsilä, better known for its numerous marine engines and naval industries. This 8-cylinder powerplant gave 1,100 kW or 1,500 hp, which combined with the overall initial weight of the serie 1 (54.5 tons) gave a ratio of 27.52 hp/tonne, unsurpassed in the west. Indeed, only today's Russian T-80U (27.2 hp/ton) and the T-90SM (26.3 hp/ton) came close, but are slightly slower, especially off-road.

This contributed to creating an image of "racetank" reminiscent of Christie's 1930s prototypes. Indeed, its top speed was well above 80 kph (on road) in initial trials, but to manage the engine long-term battlefield reliability, it was governed electrically to 72 kph (45 mph). Due to entirely revamped suspensions, the off-road capabilities are also largely over the charts, from 50 to 55 mph on average. Torque is 4850 Nm at 1700 RPM.

The power is transmitted through an automatic SESM ESM500 to the rear drive sprockets and has five forward and two reverse gears. Speeds are pre-selected and one speed could be engaged in emergency. The Leclerc is able to turn on the spot. When braking at 30 kph a hydrokinetic retarder is automatically engaged, slowing down the tank at a deceleration rate of 7 m/s² (0.7 g). Therefore the braking system is hybrid as there are in addition two manganese-ceramic disk brakes mounted beside the final drives on the rear and a mechanical parking brake. There is an electronic engine management system supplied by Safran. The acceleration is obtained by a French gas turbine acting as an "hyperbar" system, at 0-32 kph in 5.5 to 6 seconds.

This Turbomeca TM 307B gas turbine (derived from a helicopter engine and fuelled with high-octane kerosene) inside the engine acts as a turbocharger, works as an anti-lag system and an APU, providing auxiliary power to all systems when the main engine is shut down. The turbine provides a high boost pressure of 7.5 bar and an effective pressure of 32.1 bar. By comparison, the Wärtsila RTA96 diesel -the world's largest- has 18.6 bar. To reduce the infrared signature, the rear left engine exhaust is cooled with the air from the cooling fans within the hull rear. Overall, this powerplant is extremely quiet and compared well to the Abrams power unit in this respect. In addition, the location and particulars of the exhaust made it easier to the following infantry to come close. However, the exhaust flows vertically through a small pipe which avoids burning the surroundings but made it a more visible heat signature at high speed. However, the clean burning process strongly reduces this thermal signature when traveling slowly even at short range.

All this power was passed onto the ground by a new track system with double pin links, each with two sets of rubber shoes. Like the previous AMX-40, the tracks rolled on a set of six doubled roadwheels, heavenly spaced, of a new design. These are suspended by individual modern torsion bars systems which are electronically-assisted hydropneumatic modules developed by SAMM (Societe d'Applications des Machines Motrices), with a tension auto-adapting to the nature of the ground.

The tracks are supported by six return rollers and the idler are at the front. Tracks vulcanized rubber layer was tested but rejected. Autonomy is provided by an internal fuel capacity of 1300 liters of diesel, in fuel cells mounted in the frontal hull sides, acting as an extra protection. In addition, two drum tanks could be installed at the rear, of 200 liters each, which raise the capacity to 1700 liters. The operational range varied from 550 km to 650 km (400 mi), however, the fuel drums must be jettisoned if the tank is to engage targets as they are restraining the turret full traverse. The refueling system is high pressure, allowing a full replenishment in 2 minutes in the field. The tank is fully amphibious and can ford 1.1 m deep without preparation and up to 4 m with a full preparation. It is equipped with two schnorchel tubes stored on the turret's back. It could also climb 40° slopes, cross 3 m trenches, 1,25 m high obstacle.

Production Series

Many contractors and subcontractors were involved in the construction of the tank: SAMM for the ESO twin-cylinder oleo-pneumatic suspension with Goodrich Actuation System, Sagem for optronic equipments, sights, and the turret power unit, SESM & Wärtsilä for the powerplant, Thales for the onboard FCS computer, Elno for the communication set and intercom, and Nexter Munitions for the ammunition. The final assembly of the turret and main armament is done at the Tarbes facility in the south of France, while the hull assembly and final marriage are realized at the Roanne state-of-the-art assembly line (Loire dept. in central France) by NEXTER.Leclerc EMAT S1 serie

The standard early French version went into several batches and upgrades over its total production.Leclerc T1 (1990)

The "T" stands for "tranche" (batch). Basically, this was a prototypes batch. First tests in Great Britain shows the superiority of the Challenger in mobility. The first armor type was modular and comprised perforated steel plates and/or spaced armor modules. It also used external smoke grenade system (placed on the slab-sided front turret armor), but later tested the GALIX. These five vehicles are now retired and stored in reserve. In the French tradition of naming individual tanks, these were called ARES, BAYARD, CARNOT, DUROC and ESTIENNE.Leclerc T2 (1992)

More advanced turret design, extra armor mounted at the turret front, GALIX self-defense. Two lots of 17 vehicles total produced, now retired and stored. Test-beds for new technologies, or penetration tests.

Leclerc T3 (1993)

New side skirts and front hull armor design. The wider skirts are inserted with of a rubber layer to defeat RPGs. These were used for tank trials in Sweden and defects on the engine and the suspension were found and corrected. These are now used for training and instruction.Leclerc T4 (1995)

Final production version with solved engine and suspensions problems: The too sensitive engine control unit was desensitized and the equally too high fuel consumption was toned down by lowering the idling RPM from 1100 to 900 RPM. The drive sprockets were equipped with a cooling system and the navigation software was updated.Leclerc T5 (1997)

Had extra armor on the hull sides, over the side skirts, and a brand new computerized engine management. It also included modifications inside the turret and updates for the navigation and communication as well as a modified autoloader.Leclerc RT5 (1998-99)

The final upgrade for previous version. This standard includes a lowered turret drive to avoid overstress the structure, extra stowage boxes at the turret rear including a closed storage box at the left and to the right an open storage basket that can be tilted further to the right to avoid blocking the reloading hatch. There are upgraded hydropneumatic suspensions units working with hydraulic oil and nitric, in a more compact unit which is also known for a better handling and causing less stress to the structure. There is also a light and smaller fire control system and better cooling system to operate in cold conditions.Leclerc EMAT S2 serie (2000s)

Leclerc T6

Entirely revised air conditioning system for the crew, optimized to cover a larger range of extreme temperature and climates.Leclerc T7

Standard software, upgraded data transmission system between the tank commander and HQ for an instantaneous vision of the state of all battle tanks and acquired targets, and better visor.Leclerc T8

Completely upgraded electronics.Leclerc T9

Integrates a Sagem IRIS gunner numeric thermal imaging sight instead of the ATHOS system, with better resolution. This was the next upgrade standard for the previous series, starting in 2005.Leclerc EMAT S3 serie (2004-2010)

Production and upgrade package SXXI applied to all operations tanks or previous batches. Concerned 96 vehicles.Leclerc T10

New armored modules, upgraded tank commander sight assisted by a laser and the IRIS thermal camera. First showcased at Eurosatory 2010.Leclerc T11

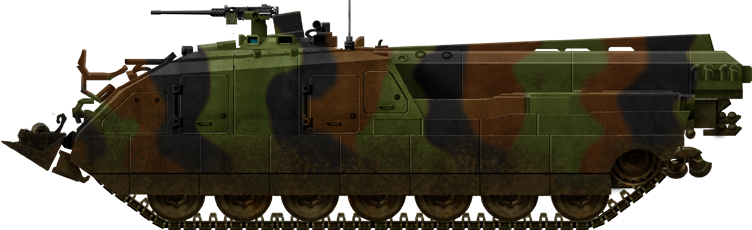

Integrates the new battle management system ICONE.Main Variant: The Leclerc EPG

Called EPG, for "Engin Principal du Génie", this Armoured Engineering Vehicle (AEV) was developed by Giat from 1994 and was first produced in 2001. It had modular capabilities that allowed some versatility, with standard installation spots for an excavator arm, clamp, shovel, auger, hoist and hook at the location of the crane. The rear deck is equipped with a standard engineering platform with a destruction kit. The front anchor blade at the front could be swapped for a dozer blade. This vehicle also served as a basis for the DNG (Dépanneur Nouvelle Génération) ARV which replace the MARS.A mine-clearing kit was provided as the K2D ("Kit De Déminage"), which comprises a 3.4 ton, 21 teeth, 4.25 m wide Pearson plow that can plunge down to 30 cm depth, the electromagnetic duplicator DEMETER, detonating cords or rocket-propelled Fuel Air Explosive stored at the back that can clear corridors 110 meters long for 4 meters wide, and pathfinders markers to define the corridor.

Prospective Variant: The Leclerc T40

A proposal from the late 2000s to convert some obsolescent series 1 (now in storage) vehicles into heavy reconnaissance scouts in the Russian BMPT-1 style. A brand new turret with a CTA CT40 Case Telescoped Weapon System (CTWS), grenade launchers, and two ATGMs were envisioned. However no order was placed yet.UAE Leclercs

Like another Paris famous Place Vendôme product, the Leclerc is small but costly. A piece of armored luxury that few nations can afford today at €6,5 million apiece in 2001 ($7,34 million), compared to the Leopard 2A6 (€5 or $5.74 million), or Challenger 2 (€3,72 or $4,2 million). That's no mystery that still today, the wealthy United Arabs Emirates is the only one foreign customer of the French MBT, even after several tailor-made modifications, also intended for Qatar (which evaluated but so far never ordered it). Today, only the Korean K2 Black Panther and Japanese Type 10, combined with the Euro massive devaluation are now ranking higher with their price tag ($8,5 and $8,4 million in 2009 respectively), perhaps a symbol of Asia's growing prosperity and military might. UAE Leclercs were defined early on, right when funds were needed to develop the new tank back in 1985. Although they share most of their equipment and design with the French Army model, they also include many modifications tailored for desert conditions and UAE Army specifications. 388 Leclerc UAE were delivered between 1994 to 2000 and in service by 1996 with specs as follows:

UAE Leclercs were defined early on, right when funds were needed to develop the new tank back in 1985. Although they share most of their equipment and design with the French Army model, they also include many modifications tailored for desert conditions and UAE Army specifications. 388 Leclerc UAE were delivered between 1994 to 2000 and in service by 1996 with specs as follows:

- Mass: 57 metric tons

- Lenght: 10.08 m

- Remote ATO 7,62 mm FN-MAG roof LMG.

- 6 Composites side armour blocks (instead of 3)

- top speed 70 kph and 0 to 32 Km/h in 6 seconds

- FNDERS-derived LBME (Leclerc Battle management equipment)

- Navigation system with two consoles (instead of the ICONE system)

- Tank commander SFIM HL-80 sights and ALIS thermal camera (x14 magnification)

- Tailored air filters, vents, louvres, cooling and air conditioning system

- No provision for deep fording or schrnorchel

- German V12 diesel MTU883 (Euro Powerpack) 1500 hp, 4545 Nm @2000 RPM

- External auxiliary diesel power unit

- German Renk HSWL295 TM automatic transmission

- Turret bustle baskets storage bins, tank infantry telephone

Active service

By 2007, 355 tanks were in operational status, 320 incorporated in four regiments, each of 80 tanks, but as of 2010 and budget cuts, As of 2010, after a French defense review, each regiment was curtailed down to 60 Leclercs for a total of 240, 100 more in combat ready reserve. By 2011 this total dwindled to 254 tanks, including those in reserve. These four regiments are the 1er Régiment de Chasseurs (Verdun, 7th Armoured Brigade), 4e Régiment de Dragons (Carnoux-en-Provence, 7th Armoured Brigade), 12e Régiment de Cuirassiers (Olivet, 2nd Armoured Brigade), 501e Régiment de Chars de Combat (Mourmelon-le-Grand, 2nd Armoured Brigade). Apart for peace-keeping operations in low-intensity conflicts in Kosovo and Lebanon it has been never deployed in major operations and remained largely untested as many today's fourth generation MBTs but the Abrams, Leopard 2 and Challenger 1 & 2.In 2003 the Greek army launched a tender for acquiring a new tank and compared the T-80U, T-84, Leclerc, M1A2 Abrams, Challenger 2E and Leopard 2A5 in a contest. The results were as follows: When firing 20 rounds at 2000 and 1500 m distance in daytime (half static, half on move), the Leclerc was the only one scoring 20 hits, but in hunter-kill capabilities scored 13 out of 20 (17 for the Leopard), and had 9 fire per minute rate (equal to the 2A5) compared to 8 to 6-7 for the others. Its tested operational range was 500 km, better than the others, ranging from 365 (Abrams) to 450 km (T-84) and raised no complaints about mobility. In last resource, the price tag seemed to be instrumental in the choice of the Leopard.

Links

The Leclerc on WikpediaFrench website dedicated to the Leclerc

Leclerc specifications |

|

| Dimensions (l-w-h): | 9.87 oa (6.88) x 3.60 x 2.62 m ( x x in) |

| Total weight, battle ready: | 54,5 to 57,4 Tons (xxx ibs) |

| Crew : | 3 (Driver, Commander, Gunner) |

| Propulsion: | SACM V8X 8-cyl, 4 stroke diesel 1,500 hp, 27.52 hp/t (1,100 Kw) |

| Suspensions: | Hydrogas-assisted torsion arms |

| Top Speed | 72 kph (45 mph) 55 kph off-road |

| Range (road)/Fuel consumption | 550 to 650 (400 mi) for 1300-1700 L |

| Armament (see notes) | Main: 120 mm sb GIAT CN120-26/52 with 40 rounds Sec: 12,7 mm M2HB coax. (1,100 rounds) Sec: 7,62 mm AA-52 LMG (3,000 rounds) |

| Armour | Classified, composite modules, NERA/ERA. |

| Total Production | 860 |

Leclerc Gallery

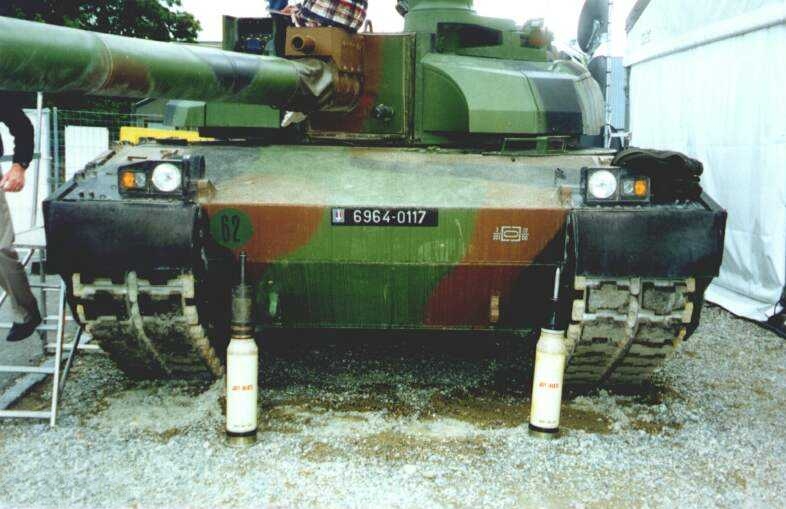

2006 Bastille day closeup:

The AMX-32 in 1982.

The AMX-40 in 1986.

Leclerc demonstrator (1st prototype "Ares", registration plate number 68940081), in trials in 1990, without side skirts. notice its slab-sided turret.

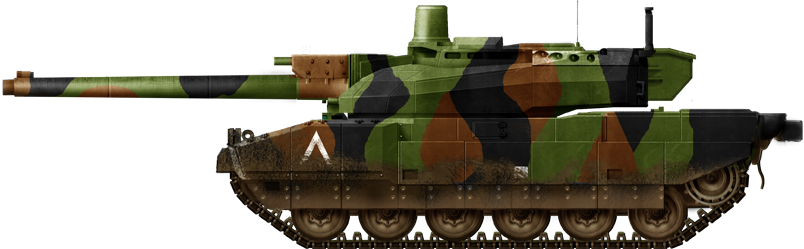

Leclerc, early production model serie I, 1993, in green livery.

Leclerc of the final RT5, last upgrade of the 1st serie, 1999.

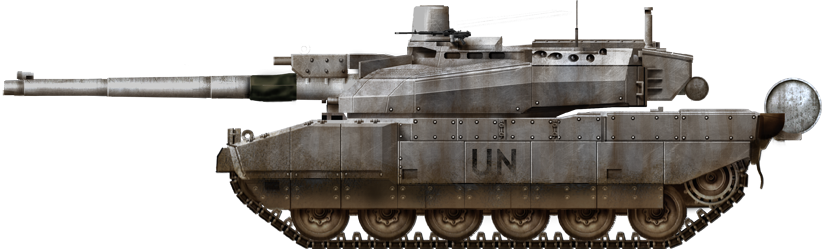

Leclerc Serie 2, UN forces in Kosovo, fall 1990s

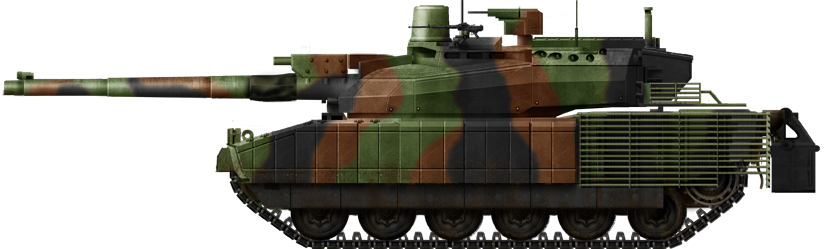

United Arabs Emirates Leclerc, 1990s

EAU Leclerc with a camouflage net and upgrades, 2000s

Leclerc with the AZUR urban protection kit in the 2010s

Leclerc EPG (EPG, Engin Principal du Génie) or ARV, 2002. This modular vehicle can receive also a minesweeping or rocket-assisted mine-cleraing DEMETER kit.

Modern Tanks

Modern MBTs posters

Denel Bagder (2018)

Type 16 MCV (2016)

Gepard 1A2 last rounds 2011

SANDF

Russian AFVs

Main Battle Tanks