Commonwealth of Australia (1942-1943)

Commonwealth of Australia (1942-1943)

Cruiser Tank – 65 Built

The only WWII Australian tank design

Among the Commonwealth nations, Canada probably had the best industrial capacities and helped Allied tank production during the war. Canadian factories built Shermans and Valentines, as well as the Ram or the Sexton, which were indigenous designs.

Australia and New Zealand had more limited industrial capacities, but nevertheless pushed on with their own designs, especially as the Japanese threat grew steadily in early 1942.

If the Bob Semple tank was an oddity, more conceived as a last ditch defensive vehicle than a real frontline tank, the Australian AC I Sentinel was a fully-fledged cruiser tank. First intended for combat in North Africa, the AC I was the first and only domestic production tank in Australia’s history.

Sketches of what would become the Australian Cruiser (AC) tank were first drawn in June 1940, when the situation in Europe was so dire that the Commonwealth was mobilized, and later dramatically escalated when war broke out with Japan in 1941.

To save time, the automotive basis had to be the American M3 Lee but with a British cruiser style low-profile turret and hull, and British armaments. However industrial limitations repeatedly hampered production, by late 1941 no prototype was ready and production only began on a limited basis in mid-1942.

The design was altered at several points along its development resulting in several distinct variations that, while innovative, ultimately did not enter production. While the AC tanks never reached substantial production they did display a remarkably refined design for a country that had no prior history with the production of AFVs, as well as several notable features such as the mostly cast hull, whereas most contemporary British tanks still had welded/riveted plates.

Preserved RAAC Sentinel AC1 Cruiser Mk.1 Australian WW2 Tank in the Australian Armour and Artillery Museum, Cairns, Queensland, Australia

Initial attempts at design

The first steps towards an Australian tank began on the 12th of June 1940 at a meeting between representatives of the Australian Military, Prime Minister Robert Menzies and Director General of the Ministry of Munitions, Essington Lewis. Chief of the General Staff (CGS) Sir Brudenell White announced the Army’s intention for the Master General of Ordnance (MGO) branch to produce a light cruiser tank in the range of 10 tonnes with a requirement for 859 vehicles by the end of 1941.

The AC I under construction at the Chullora tank annex. (Source:- Australian War Memorial)

At this point in time, no official CGS design specification had been issued however. The Army design section under control of Major (later Lt.Colonel) Alan Milner, had nonetheless produced a design by the end of the same month. The intended vehicle had a proposed weight of 12 tonnes, of which 7 tonnes represented all round armored protection on a basis of 28 mm (1.1 in), powered by twin Ford Mercury engines.

Primary armament was to be the QF Vickers 2-Pounder (40 mm/1.57 in) gun accompanied by one .303 (7.7 mm) machine gun and one 2” (50.8 mm) trench mortar. In light of the deteriorating situation in Europe by August of 1940, the Australian Army had revised their requirement to a 15 tonne tank with heavier armor.

Although the Army had revised the requirements for the proposed tank, still no design specification had been issued by the CGS. Realising that undue delay was occurring in the design of the Australian tank, Prime Minister Menzies telegrammed the War Office on the 20th of August 1940 requesting the loan of one or more tank design experts to assist the Australian project. A reply was received on the 4th of October 1940 announcing the dispatch of Colonel W D Watson (MC) of the Royal Artillery to Assist.

Watson did not travel directly to Australia, instead crossing to the United States where he rendezvoused with Australian engineer Alan H Chamberlain to make a join assessment of tank developments in the USA and Canada. During the same month, information was received from Australian representatives in the USA indicating that the current design for a 15 tonne tank was not sufficient to compete with German tanks.

Australian Cruiser Tank AC1 Sentinel at the Tank Museum Bovington, England

The recommendations called for a design based on the current Anglo-American design (what would become the M3 Lee/Grant medium tank), a 25 tonne tank with a minimum armour basis of 60 mm, preferably 80 mm (2.36-3.15 in), and a 350 hp aircraft type engine.

The formal CGS specification for an Australian produced cruiser tank was finally issued on the 11th of November 1940. The CGS specification was a lengthy document still cluttered by the technological indecision and tactical confusion that had prevailed previously.

The major points were as such. An immediate requirement for 340 tanks to equip one armored division and a further 119 tanks for the 1st Australian Corps and the AMF (84 and 35 respectively), an additional 400 tanks for 12 months reserve, with a total production of 859 tanks. No weight restriction was issued beyond the lowest possible allowing for all other requirements to be met, with armor required at 50 mm (1.97 in) minimum, although this was later amended to 65 mm (2.56) frontal with 45 mm (1.77 in) minimum sides and rear.

RAAC tank crew on their new Australian Cruiser Tank AC1 Sentinel

Dimensions were restricted to conform to the loading gauge of Australian railways, a maximum width of 9 feet 4 inches and maximum height of 8 feet 6 inches with no restriction on maximum length. In regards to mobility, it was requested that the tank be able to operate on sand or black soil, with no requirement for cold weather operation.

Minimum required top speed was to be 35 mph (55 km/h) on level ground, with a slope traverse of 45 degrees, and trench and vertical obstacle crossing capabilities of 6 foot 6 inches and 3 foot 6 inches respectively. Operational range was specified as a minimum cruising range of 150 miles (240 kilometres).

Armament was to be one Ordnance QF 2 Pounder accompanied by one .303 machine gun mounted in the turret with another machine gun mounted in the hull considered desirable. Minimum ammunition load was set at 120 2-pounder shells and 5000 rounds of small arms ammunition for the machine guns (7000 if two guns were mounted).

All weapons were to have a minimum elevation of 36 degrees and minimum depression of 10 degrees. A requirement for 12% of tanks to be equipped with armament capable of smoke laying and firing High Explosive shells for Close Support (CS) purposes was also presented. Additionally supply and anti-aircraft tanks were also listed as requirements but specified as requiring their own separate design brief.

Design of the Australian cruiser

Col Watson arrived in Australia in late December of 1940 and was immediately appointed head of design for the Tank project. Based on the industrial conditions of Australia the AC I borrowed multiple elements of the M3, in particular the drive train and suspension layout, however extensive modifications had to be made in order for the tank to be produced locally.

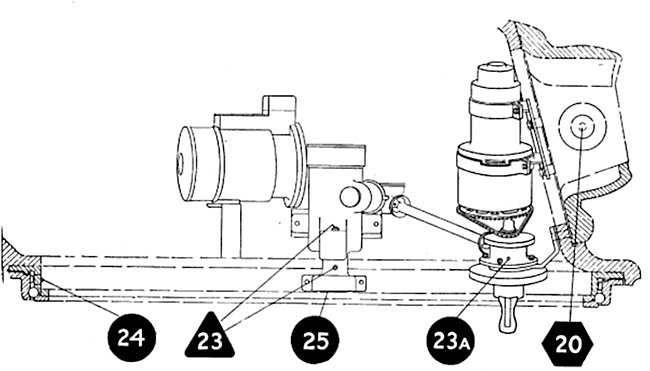

Diagram of the major castings of the AC I tank. Source: National Australian Archives MP730 10

With the tank project arriving at a relatively late juncture in the Australian munitions program there were no available facilities equipped to roll armored plate in the thicknesses required. The solution devised was to cast the hull in six sections which would be bolted or welded together to form a rigid whole. Additionally, Australian stocks of nickel, typically used in cast armour, were earmarked as critical war resources and thus unavailable.

To deal with the nickel problem metallurgists at Broken Hill Proprietary (BHP) developed a new armored steel formula, Australian Bulletproof Plate 4 (ABP4), utilising zirconium in place of nickel. Zirconium was chosen due to Australia possessing some of the world’s largest readily available stocks of naturally occurring zircon sand.

The engine presented yet another problem. In order to meet the army’s requirement of a 35 mph (55 km/h) top speed it was estimated that an engine of at least 300 hp would be needed. However, both the intended original engines, the radial Pratt & Whitney Wasp and the Guiberson diesel, were not available.

The Pratt & Whitney Wasp had been produced in Australia under licence by the Commonwealth Aircraft Corporation (CAC) since the mid-1930s, but immediate war needs meant that all Australian Wasp production was tied up in aircraft orders for Australia and the UK. To circumvent the engine issue, Watson proposed the use of three regular Cadillac V8 346 in³ 5.7L engines, arranged in a clover-leaf formation through a transfer case leading into a common driveshaft, giving a total output of 330 horsepower.

In April of 1941 the clover leaf Cadillac setup was assessed by Professor Burstal of the University of Melbourne and the Chief engineer of the Vacuum oil Company, Mr Alfred Reginald Code, with both men concurring that while the setup was less than ideal it would be workable as an expediency.

The last issue to be overcome was that of the gearbox. The US M3 Medium tank used a state of the art synchromesh gearbox with helical toothed hardened steel gears running on multiple bearing races, and was difficult to produce even in the USA. In Australia, the machinery required to cut gears of that type was not available and a shortage of bearings meant that the synchromesh gearbox could not be manufactured in Australia. The solution was to simplify the gearbox to a crash type design that used the same gear blanks and maintained the dimensions of the synchromesh type. This meant that the gearbox could be replaced with the more modern type should supplies become available from the USA. The gearboxes were produced by the firms Coote & Jorgensen, and Sonnedales.

While remarkable progress had been made in the first six months of 1941, the AC I was still on the drawing board and no closer to the arrival of a pilot model. Noting the inefficiencies of the established organisation Prime Minister Menzies again intervened in June of 1941 to create the Directorate of Armoured Fighting Vehicles Production (originally titled AFV division), with Alfred Reginald Code appointed as Director. Code was known both as a respected engineer and a skilled administrator and Prime Minister Menzies deliberately gave the DAFVP an unorthodox structure beyond both the Ministry of Munitions and the Army in an attempt to fast track tank production.

Code immediately set to building a skilled staff of designers and production engineers in order to simplify the tank design into the most viable design for Australian industry. Australian foundries had been emboldened by the idea of a cast hull for the tank and insisted that not only was it possible, but that it could be cast as a single large piece with only the axle housing and other external fittings being bolted on separately.

Proof of this concept was borne out in August-September of 1941, when the first test hulls were cast in foundries at the New South Wales city of Newcastle. The one piece cast hull reduced the amount of time required in machining and assembling the tank. Additionally, the new team at the DAFVP made several revisions to the design to streamline assembly. This included modifying the final drive design so that they could be installed from the side after the axle housing had been fitted and implementing a new ‘scissor’ type Horizontal Volute Spring Suspension (HVSS) bogie, resembling the French Hotchkiss H35, which offered equal performance to the American type while being easier to manufacture.

The suspension changed configuration during the development stage, with prototype vehicles having a trailing return roller, and production vehicles having the return roller on top. The AC I was designed to be able to use either locally produced steel tracks of a similar configuration to those used on British Cruiser tanks or alternatively US produced rubber block tracks. Installation of each type of track required the fitting of a different drive sprocket. Australian manufactured road wheels were functionally identical to US produced M3 road wheels, however they can be identified by either 4, 6, or 8 holes drilled radially around the inner diameter of the wheel.

The turret was fully cast with a 54 inch (1.37 m) turret ring, very similar to the British cruiser design, and the hull kept a low profile as intended. Armament was also similar to the British tanks, with the Ordnance QF 2-Pounder (40 mm/1.57 in) as the main armament. Due to the BESA machine gun not being in production in Australia, secondary armament consisted of one coaxial Vickers .303 (7.7 mm) machine gun and one hull mounted Vickers .303 machine gun protected by a massive cast armor mantlet, encasing the machine-gun watertank.

Ammunition for the main gun was 46 rounds stowed horizontally in the rear of the turret with 74 rounds stowed vertically in two racks bolted to the hull floor under the turret basket. The turret was rotated either manually or via an electric power traverse. The traverse mechanism was a 40 volt system with current drawn from a dynamo in the transfer box linking the three engines to the main drive shaft. To ensure consistent power supply at variable RPM three shunt motors were provided to stabilize the current flow.

Diagram of the turret traverse mechanism of the AC I. The main traverse motor and traverse gear is leftmost, manual traverse hand wheel, traverse control motor and sprocket linkage are on the right, Source: Australian Cruiser Mark I Instruction book

The manual traverse wheel was linked directly to the main turret traverse motor as well as to the traverse control motor via a sprocket linkage. Under manual power the traverse motor armature was immobilized via a solenoid brake. This meant that the gunner did not have to overcome additional resistance from the turret motor while using manual traverse. For power traverse a grip trigger on the traverse hand wheel disengaged the manual gearing and engaged input to the control motor via the sprocket linkage.

An interesting feature of this setup was that the turret control motor possessed a separate control hand wheel that could be used to run the main traverse motor at a constant rate. This allowed for a technique where the gunner could set the traverse mechanism to run at a constant rate and then, using manual traverse, cause the turret gearing to ‘run back’ in order to make precise adjustments to aim while rotating the turret. This feature was touted as being beneficial to making accurate shots against moving targets.

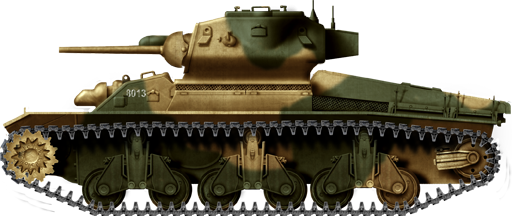

Australian Cruiser Tank Mark I (AC I) number 8013 during tests near Sydney, early 1943. A design influenced by the British Crusader and the M3 Lee, using local and US tank parts. Despite having stronger armor than the British Cruiser VI, this model was never tested in combat. In a what-if scenario, they would have not even been ready for action in Tunisia.

Construction

Despite the streamlining of the AC I and using many parts already available from other tank designs, the development took time. The automotive prototype of the definitive design, entitled E1, came out in January 1942. In February 1942, a memo was issued from the Army Director of AFVs, Lt.Colonel Crouch, officially formalising the name of the AC I as Sentinel.

The second prototype, E2, arrived in March of 1942. Armor casting was conducted at the Bradford & Kendall foundry annex in Alexandria, Sydney. Hulls were cast in hand packed sand moulds before being transferred to the first of 6 electric tempering furnaces. Hulls were produced at a rate such that each hull moved to the next tempering furnace in the series in time with a fresh hull being removed from the mould, for a total rate of 5 hulls per week.

(From left to right) Minister of Munitions Norman Makin, Field Marshal Sir Thomas Blamey and Director of Armoured Fighting Vehicles Production Alfred Reginald Code inspect the AC I E2 prototype at a demonstration of AFVs at DAFVP headquarters, Fishermans Bend, Port Melbourne Victoria. April 1942. Source: Australian War Memorial

An industrial mould packing machine was purchased from the USA but shipping delays meant that it did not arrive until late 1942 at which point the Bradford & Kendall foundry men were confident that they could hand pack the moulds at the same rate as the machine. It therefore went unused. Assembly of AC I tanks was contracted to New South Wales Government Railways with work carried out at Chullora Tank Assembly Workshops at Chullora, Sydney.

The Chullora Tank Assembly Workshops were repurposed for construction and maintenance of rail stock post war, and still exist to this day. The first production vehicle (no. 8001) arrived in July of 1942. The first 12 vehicles delivered were found to suffer from temper brittleness, which caused certain pieces of casting to inconsistently harden during the tempering process. As a result, the armor of these tanks was deemed potentially unreliable and subsequently labelled as ‘unarmored’.

An additional post tempering water quench was introduced to solve the problem in subsequent hulls produced. ABP4 plate was evaluated as being equal in resistance to British cast armor and slightly less hard than American cast armor, while displaying remarkably low levels of spalling or flaking on impact.

The first allotment of tanks began trials in August 1942 with trials completing in January of 1943. Full production of AC I tanks totalled 65 and the 2 prototype machines, delivered to the Army from November 1942 to June 1943. Despite delivery to the Army, no AC tanks were accepted for active use by Australian units. As such, no tanks were issued with Army Vehicle Registration Numbers (AVRN).

Standard camouflage for AC I tanks was the mid 1942 Australian two tone camouflage scheme of light stone base with green swatches. An additional interesting feature for a cruiser tank was the installation of a Graviner methyl bromide fire suppression system in the engine bay, which could be activated either manually by the driver or automatically by flame switches in the engine bay.

Photo of the turret ring, ammunition stowage, and engine setup. The transfer case is the rectangular object in the lower centre of shot, the front two engines and rear engine drive shaft can be seen through the access hatch on the fighting compartment firewall. Source: Ed Francis

Chullora Tank Assembly Workshop, January 1943. Sentinel tank hulls can be seen progressing down the production line on the left with accompanying turrets on the centre line. Completed tanks are present on the right. M3 Lee tanks are also present undergoing refits and refurbishment. Source: NSW state records

Never tested in combat

The termination of the entire Australian Cruiser program in mid-1943 was dictated by a mixture of practical and budgetary reasons as well as an ongoing political rivalry between the Ministry of Munitions and the Army. Testing of the AC I tanks had revealed several issues with the vehicles, some major and others sundry.

The main issues consisted of problems with cooling the triple Cadillac engines, weaknesses in the turret traverse mechanism (this was due to the turret being balanced for the weight of a 6 pounder gun and therefore being unbalanced when fitted with the 2 pounder), and unacceptably high rate of wear on the road wheel rubber. Granted, many similar problems were common in the early models of a lot of tanks, and the DAFVP were confident that they had identified the causes of the problems and could rectify them, but the delays to production that these problems entailed were ultimately too severe and too costly to be acceptable to the Army and Government.

The Lend-Lease authorities in the USA had also become increasingly sceptical of the Australian tank program and it was considered that the resources used in producing Australian tanks could be better used in maintaining and expanding Australia’s increasingly neglected rail network, in order to better support the increasing Allied presence in the country.

Considering that the proven M4 Sherman was now available in substantial quantity from the USA and the decreased threat of the Imperial Japanese Navy to Allied shipping it was argued that imported vehicles were a more cost effective and immediate means to fulfil Australia’s armour requirements. Entreaties were made to divert an allotment of M4 tanks from stocks earmarked for delivery to the UK, however only 2 M4 tanks arrived in Australia for tropical testing and were subsequently transferred into custody of the Army.

Both M4 tanks are now on display at the Royal Australian Armoured Corps museum at Puckapunyal base, Victoria. Additionally, Australia was now fully committed to a war in the Pacific and the idea of an African or European campaign against German and Italian forces was a distant memory.

In 1943, the need for tanks was seen as drastically lower in the Pacific theatre and the experience of facing German anti-tank guns in North Africa had diminished the perceived effectiveness of tanks. As a result, the requirement for tanks had been reduced from 859 to 434 and the majority of Australia’s nascent armoured divisions had been disbanded.

Due to the lack of need to equip armored units, the entire stock of AC I tanks was never shipped abroad, but kept for training and testing purposes instead, then placed into storage until being declared obsolete after the end of the war.

A few tanks operated by crews from the 3rd Army Tank Battalion made an appearance (under German colours) during the 1944 “Rats of Tobruk” movie, firing blank shells. After the war, all but three AC tanks were sent for scrap although some hulls were modified and refitted with commercial engines for use as cheap industrial or agricultural tractors.

Surviving AC I Sentinels are displayed today at Bovington and Puckapunyal museums, as well as an example constructed from a salvaged hull and turret on display at the Australian Armour and Artillery Museum.

Gallery

Sentinel AC I tank undergoing trials. Source:- Australian War Memorial 101156

Sentinel AC I tank on exercise.

Preserved AC I on display at the RAAC museum – Credits: Wikimedia Commons

AC I Sentinel specifications |

|

| Dimensions | 6.32 x 2.77 x 2.56 m (20’9” x 9’7” x 8’4”) |

| Total weight, battle ready | 28 tons |

| Crew | 5 (commander, loader, gunner, driver, machine gunner) |

| Propulsion | 3 x V8 Cadillac 330 hp total, 12 hp/t |

| Suspensions | Horizontal volute springs (HVSS) |

| Max speed | 48 km/h (30 mph) |

| Range (max) | 240 km (150 mi) |

| Armament : | 2-Pounder QF (40 mm/1.57 in), 130 rounds 2x Vickers .303, (7.9 mm) 4250 rounds |

| Armor | From 45 to 65 mm (1.77-2.56 in) |

| Total production | 65 |

Links and Resources

Australian War Memorial Archives

The AC Sentinel on Wikipedia

Tank Hunter

17 replies on “AC I Sentinel Cruiser Tank”

Can you do an article about the AC 2 and AC 3?

In production as we speak.

– TE Moderator

Love this indigenous tank, *** the americans with their garbage, lol.

On another note, thanks to the OP of the site for calling it “The Netherlands” and not perpetuating the fallacy ” Holland”

(could not post that in the correct page, as there was no reply option)

Yoo AC1 is skits tank, im aussie myself so like this 🙂 Great post thanks Guys!

yeknow i love Aussie, but i really wish they had better tanks.

For a first attempt I’d say it was quite a decent tank. Certainly better then then current Italian and other second line (non-major WW2 participants).

It’s struck me how similar the hull hatches to those of the M3 Medium. I wonder if anyone’s ever looked into whether they are the same.

I can never work out if the M3 Mediums Australia had were to be donors for the suspension or if the suspension was to be newly built.

The hatches aren’t the same as on the M3 medium, there may be some superficial similarity but the design is completely different.

As for the suspension the AC1 used a locally designed and manufactured bogie based off of the French Hotchkiss type. The M3 type used a pair of volute springs set vertically and actuated independently by the front and back swing arms of the bogie, the Australian type used a single volute spring set horizontally with the front and back swing arms attached to the front and back of the spring with an additional small coil spring attached to the back swing arm as a shock absorber. The Australian type was made of less parts which made it easier to produce locally with fewer machines and requiring less time and manpower.

M3 bogies were tested on a few AC1 tanks and found to work satisfactorily as an alternative, however they required the mounting plates on the hull to be modified to match the different bolt configuration on the M3 bogies. Additionally there were plans for AC1 tanks produced at the Victorian workshop to use american produced components, including M3 suspension bogies if available, however the Victorian workshop never reached production readiness before the Tank project was cancelled.

TE Moderator, Author

We seriously not gonna mention the Mg on the hull that looks like male private parts?

Nope

Note the tank in the background of the first photo is AC 3 thunderbolt. Experimental mounting of 17pndr. First tank to mount this

In the first pic (Aust. Armour and Artillery Museum) is 8040 which is a production AC1 and like all AC1 originally had a 2 pounder. 8040 was at Puckapunyal for many years, with a 37mm barrel as its 2 pounder was missing. It was never used for 17 pounder testing, this barrel has been fitted by the people at Cairns. The 17 pounder (as well as the 25 pounders) was tested on the first prototype, E1, which can be identified as it was the only AC1 tank with a multi-piece hull.

8006 (in the foreground) was restored in 1995-6 by the owner of the Melbourne Tank Museum, Mr John Belfield. As one of the first dozen tanks, is mild steel. In 2006 it was purchased by Jacques Littlefield. When his collection was sold off, it came back to its home country. 8030 is at Puckapunyal, and Bovington’s AC1 is 8049. The AWM in Canberra has 8065, the only AC3 built.

Zim

Hang on, the AC3 might be 8066.

Australia actually received THREE Shermans for trials during WW2 – 2xM4 and 1xM4A2.

After trials were completed one of the M4 machines was used as a range target. The remaining pair were placed into the museum at Pucka.

https://en.wikipedia.org/wiki/Lend-Lease_Sherman_tanks#Australia

I’ve got some of the doccumentation on the Madang trials of the M4 and the Churchill tanks. I’ll do an article on it eventually, possibly throw in the M24 chaffees that were trialled too If I can find enough information.

TE Moderator, Author

The war memorial has a 20-minute newsreel video of the trials:

https://www.awm.gov.au/collection/F07352/

I’m just curious, on the second photo with the tank crew, one man is showing up from the manhole, so, what is this just below him? And why it is shaped like this?